XCHART Statement: SHEWHART Procedure

Example 18.35 Estimating the Process Standard Deviation

Note: See Estimating the Process Standard Deviation in the SAS/QC Sample Library.

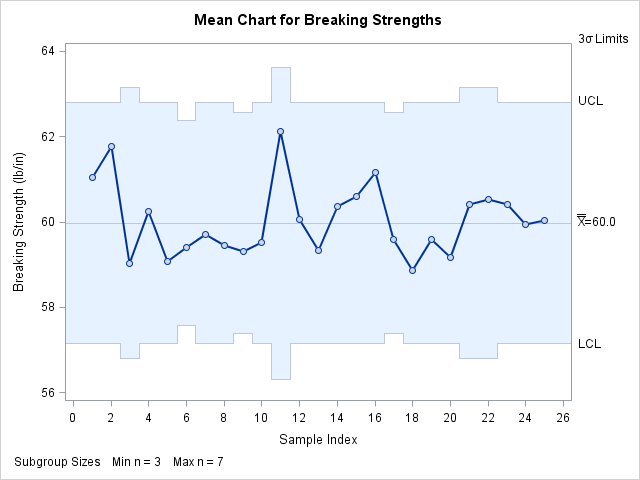

The following data set (Wire) contains breaking strength measurements recorded in pounds per inch for 25 samples from a metal wire manufacturing process.

The subgroup sample sizes vary between 3 and 7.

data Wire;

input Sample Size @;

do i=1 to Size;

input Breakstrength @@;

output;

end;

drop i Size;

label Breakstrength ='Breaking Strength (lb/in)'

Sample ='Sample Index';

datalines;

1 5 60.6 62.3 62.0 60.4 59.9

2 5 61.9 62.1 60.6 58.9 65.3

3 4 57.8 60.5 60.1 57.7

4 5 56.8 62.5 60.1 62.9 58.9

5 5 63.0 60.7 57.2 61.0 53.5

6 7 58.7 60.1 59.7 60.1 59.1 57.3 60.9

7 5 59.3 61.7 59.1 58.1 60.3

8 5 61.3 58.5 57.8 61.0 58.6

9 6 59.5 58.3 57.5 59.4 61.5 59.6

10 5 61.7 60.7 57.2 56.5 61.5

11 3 63.9 61.6 60.9

12 5 58.7 61.4 62.4 57.3 60.5

13 5 56.8 58.5 55.7 63.0 62.7

14 5 62.1 60.6 62.1 58.7 58.3

15 5 59.1 60.4 60.4 59.0 64.1

16 5 59.9 58.8 59.2 63.0 64.9

17 6 58.8 62.4 59.4 57.1 61.2 58.6

18 5 60.3 58.7 60.5 58.6 56.2

19 5 59.2 59.8 59.7 59.3 60.0

20 5 62.3 56.0 57.0 61.8 58.8

21 4 60.5 62.0 61.4 57.7

22 4 59.3 62.4 60.4 60.0

23 5 62.4 61.3 60.5 57.7 60.2

24 5 61.2 55.5 60.2 60.4 62.4

25 5 59.0 66.1 57.7 58.5 58.9

;

The following statements request an  chart, shown in Output 18.35.1, for the breaking strength measurements:

chart, shown in Output 18.35.1, for the breaking strength measurements:

ods graphics on;

title 'Mean Chart for Breaking Strengths';

proc shewhart data=Wire;

xchart Breakstrength*Sample / odstitle = title

markers;

run;

Output 18.35.1:  Chart with Varying Subgroup Sample Sizes

Chart with Varying Subgroup Sample Sizes

Note that the control limits vary with the subgroup sample size. The sample size legend in the lower left corner displays the minimum and maximum subgroup sample sizes.

By default, the control limits are  limits estimated from the data. You can use the STDDEVIATIONS

option and the SMETHOD=

option to specify how the estimate of the process standard deviation

limits estimated from the data. You can use the STDDEVIATIONS

option and the SMETHOD=

option to specify how the estimate of the process standard deviation  is to be computed, as illustrated by the following statements:

is to be computed, as illustrated by the following statements:

proc shewhart data=Wire;

xchart Breakstrength*Sample / outlimits=Wirelim1

outindex ='Default-Ranges'

nochart;

xchart Breakstrength*Sample / outlimits=Wirelim2

stddeviations

outindex ='Default-Stds'

nochart;

xchart Breakstrength*Sample / outlimits=Wirelim3

smethod =mvlue

outindex ='MVLUE -Ranges'

nochart;

xchart Breakstrength*Sample / outlimits=Wirelim4

stddeviations

smethod =mvlue

outindex ='MVLUE -Stds'

nochart;

xchart Breakstrength*Sample / outlimits=Wirelim5

stddeviations

smethod =rmsdf

outindex ='RMSDF -Stds'

nochart;

run;

The STDDEVIATIONS option specifies that the estimate is to be calculated from subgroup standard deviations rather than subgroup

ranges, the default. The SMETHOD= option specifies the method for estimating  . The default method estimates

. The default method estimates  as an unweighted average of subgroup estimates of

as an unweighted average of subgroup estimates of  . Specifying SMETHOD=MVLUE requests a minimum variance linear unbiased estimate, and specifying SMETHOD=RMSDF requests a weighted

root-mean-square estimate. For details, see Methods for Estimating the Standard Deviation.

. Specifying SMETHOD=MVLUE requests a minimum variance linear unbiased estimate, and specifying SMETHOD=RMSDF requests a weighted

root-mean-square estimate. For details, see Methods for Estimating the Standard Deviation.

The variable _STDDEV_ in each OUTLIMITS=

data set contains the estimate of  . The OUTINDEX=

option specifies the value of the variable

. The OUTINDEX=

option specifies the value of the variable _INDEX_ in the OUTLIMITS= data set and is used here to identify the estimation method.

The following statements merge the five OUTLIMITS= data sets into a single data set, which is listed in Output 18.35.2:

data Wlimits; set Wirelim1 Wirelim2 Wirelim3 Wirelim4 Wirelim5; keep _index_ _stddev_; run;

Output 18.35.2: The Data Set WLIMITS

The  chart shown in Output 18.35.1 uses the default estimate listed first in Output 18.35.2 (

chart shown in Output 18.35.1 uses the default estimate listed first in Output 18.35.2 ( ). In this case, there is very little difference in the five estimates, because the sample sizes do not differ greatly. In

general, the MVLUE’s are recommended with large sample sizes (

). In this case, there is very little difference in the five estimates, because the sample sizes do not differ greatly. In

general, the MVLUE’s are recommended with large sample sizes ( ).

).