The VARCOMP Procedure

Gauge Repeatability and Reproducibility Analysis

In a typical gauge R&R experiment, each operator ( ) makes multiple observations on each of several similar parts (

) makes multiple observations on each of several similar parts ( ) from a monitored process. The statistical model used to describe the response variable is the balanced two-factor crossed

random model with interaction

) from a monitored process. The statistical model used to describe the response variable is the balanced two-factor crossed

random model with interaction

![\[ y_{ijk} = \mu _ y + P_ i + O_ j + (PO)_{ij} + E_{ijk} \]](images/statug_varcomp0020.png)

where  is an unknown constant, and

is an unknown constant, and  are jointly independent normal random variables with means of zero and variances

are jointly independent normal random variables with means of zero and variances  and

and  , respectively. The corresponding SAS statements are as follows:

, respectively. The corresponding SAS statements are as follows:

proc varcomp method=grr; class P O; model y = P|O; run;

The first random effect in the MODEL statement is assumed to be the "Part" effect and the second is "Operator."

The ANOVA table for the preceding model is shown in Table 121.2.

Table 121.2: GRR Analysis of Variance

|

Source |

DF |

Mean Square |

Expected Mean Square |

|---|---|---|---|

|

Parts(P) |

|

|

|

|

Operators(O) |

|

|

|

|

P |

|

|

|

|

Error(E) |

|

|

|

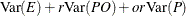

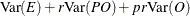

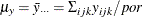

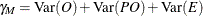

The gauge R&R parameters of interest are given in Table 121.3 in terms of  and

and

Table 121.3: Gauge R&R Parameters

|

Parameter |

Formula |

|---|---|

|

Mean of population of measurements |

|

|

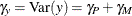

Variance of the monitored process |

|

|

Variance of the measurement system |

|

|

Total variance of the response variable |

|

|

Ratio of process variance to measurement variance |

|

|

Proportion of total variance due to the process |

|

|

Proportion of total variance due to the measurement |

|

|

Signal-to-noise ratio |

|

|

Discrimination ratio |

|

For a one-way model,  and for a two-way model with no interaction,

and for a two-way model with no interaction,

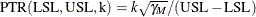

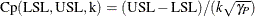

If you use the SPECLIMITS option to give specification limits, the two parameters in Table 121.4 will also be estimated and displayed.

Table 121.4: Gauge R&R Parameters Related to Specification Limits

|

Parameter |

Formula |

|---|---|

|

Precision-to-tolerance ratio |

|

|

Process capability ratio |

|

Here, USL and LSL are the specification limits, and the value k corresponds to the number of standard deviations between the "natural" tolerance limits of a normal process.

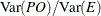

If you use the RATIO option, the ratios in Table 121.5 will also be estimated and displayed.

Table 121.5: Gauge R&R Ratios

|

Ratio |

Formula |

|---|---|

|

Ratio of process variance to total variance |

|

|

Ratio of operator variance to total variance |

|

|

Ratio of process by operator variance to total variance |

|

|

Ratio of process variance to residual variance |

|

|

Ratio of operator variance to residual variance |

|

|

Ratio of process by operator variance to residual variance |

|