The LP Procedure

- Overview

-

Getting Started

-

Syntax

-

Details

Missing ValuesDense Data Input FormatSparse Data Input FormatConverting Any PROC LP Format to an MPS-Format SAS Data SetConverting Standard MPS Format to Sparse FormatThe Reduced Costs, Dual Activities, and Current TableauMacro Variable _ORLP_PricingScalingPreprocessingInteger ProgrammingSensitivity AnalysisRange AnalysisParametric ProgrammingInteractive FacilitiesMemory ManagementOutput Data SetsInput Data SetsDisplayed OutputODS Table and Variable NamesMemory Limit

Missing ValuesDense Data Input FormatSparse Data Input FormatConverting Any PROC LP Format to an MPS-Format SAS Data SetConverting Standard MPS Format to Sparse FormatThe Reduced Costs, Dual Activities, and Current TableauMacro Variable _ORLP_PricingScalingPreprocessingInteger ProgrammingSensitivity AnalysisRange AnalysisParametric ProgrammingInteractive FacilitiesMemory ManagementOutput Data SetsInput Data SetsDisplayed OutputODS Table and Variable NamesMemory Limit -

Examples

An Oil Blending ProblemA Sparse View of the Oil Blending ProblemSensitivity Analysis: Changes in Objective CoefficientsAdditional Sensitivity AnalysisPrice Parametric Programming for the Oil Blending ProblemSpecial Ordered Sets and the Oil Blending ProblemGoal-Programming a Product Mix ProblemA Simple Integer ProgramAn Infeasible ProblemRestarting an Integer ProgramAlternative Search of the Branch-and-Bound TreeAn Assignment ProblemA Scheduling ProblemA Multicommodity Transshipment Problem with Fixed ChargesConverting to an MPS-Format SAS Data SetMigration to OPTMODEL: AssignmentMigration to OPTMODEL: Multicommodity Transshipment

An Oil Blending ProblemA Sparse View of the Oil Blending ProblemSensitivity Analysis: Changes in Objective CoefficientsAdditional Sensitivity AnalysisPrice Parametric Programming for the Oil Blending ProblemSpecial Ordered Sets and the Oil Blending ProblemGoal-Programming a Product Mix ProblemA Simple Integer ProgramAn Infeasible ProblemRestarting an Integer ProgramAlternative Search of the Branch-and-Bound TreeAn Assignment ProblemA Scheduling ProblemA Multicommodity Transshipment Problem with Fixed ChargesConverting to an MPS-Format SAS Data SetMigration to OPTMODEL: AssignmentMigration to OPTMODEL: Multicommodity Transshipment - References

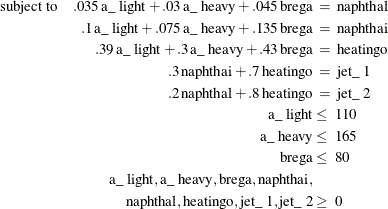

A simple blending problem illustrates the dense and sparse input formats and the use of PROC LP. A step in refining crude oil into finished oil products involves a distillation process that splits crude into various streams. Suppose there are three types of crude available: Arabian light, Arabian heavy, and Brega. These types of crude are distilled into light naphtha, intermediate naphtha, and heating oil. These in turn are blended into jet fuel using one of two recipes. What amounts of the three crudes maximize the profit from producing jet fuel? A formulation to answer this question is as follows:

The following data set gives the representation of this formulation. Notice that the variable names are the structural variables, the rows are the constraints, and the coefficients are given as the values for the structural variables.

data;

input _id_ $17.

a_light a_heavy brega naphthal naphthai

heatingo jet_1 jet_2

_type_ $ _rhs_;

datalines;

profit -175 -165 -205 0 0 0 300 300 max .

naphtha_l_conv .035 .030 .045 -1 0 0 0 0 eq 0

naphtha_i_conv .100 .075 .135 0 -1 0 0 0 eq 0

heating_o_conv .390 .300 .430 0 0 -1 0 0 eq 0

recipe_1 0 0 0 0 .3 .7 -1 0 eq 0

recipe_2 0 0 0 .2 0 .8 0 -1 eq 0

available 110 165 80 . . . . . upperbd .

;

The same model can be specified in the sparse format, as follows. This format enables you to omit the zero coefficients.

data;

format _type_ $8. _col_ $8. _row_ $16. ;

input _type_ $ _col_ $ _row_ $ _coef_ ;

datalines;

max . profit .

eq . napha_l_conv .

eq . napha_i_conv .

eq . heating_oil_conv .

eq . recipe_1 .

eq . recipe_2 .

upperbd . available .

. a_light profit -175

. a_light napha_l_conv .035

. a_light napha_i_conv .100

. a_light heating_oil_conv .390

. a_light available 110

. a_heavy profit -165

. a_heavy napha_l_conv .030

. a_heavy napha_i_conv .075

. a_heavy heating_oil_conv .300

. a_heavy available 165

. brega profit -205

. brega napha_l_conv .045

. brega napha_i_conv .135

. brega heating_oil_conv .430

. brega available 80

. naphthal napha_l_conv -1

. naphthal recipe_2 .2

. naphthai napha_i_conv -1

. naphthai recipe_1 .3

. heatingo heating_oil_conv -1

. heatingo recipe_1 .7

. heatingo recipe_2 .8

. jet_1 profit 300

. jet_1 recipe_1 -1

. jet_2 profit 300

. jet_2 recipe_2 -1

. _rhs_ recipe_1 0

;

Because the input order of the model into PROC LP is unimportant, this model can be specified in sparse input in arbitrary row order. Example 5.2 in the section Examples: LP Procedure demonstrates this.

The dense and sparse forms of model input give you flexibility to generate models using the SAS language. The dense form of the model is solved with the statements

proc lp; run;

The sparse form is solved with the statements

proc lp sparsedata; run;

Example 5.1 and Example 5.2 in the section Examples: LP Procedure continue with this problem.

As default, PROC LP uses the most recently created SAS data set as the problem input data set. However, if you want to input

the problem from a specific SAS data set, use the DATA= option. For example, if the previous dense form data set has the name DENSE, the PROC LP statements can be written as

proc lp data=dense; run;

In the previous dense form data set, the _ID_, _TYPE_, and _RHS_ variables are special variables in PROC LP. They stand for id variable, type variable, and right-hand-side variable. If you

replace those variable names with, for example, ROWNAME, TYPE, and RHS, you need the problem definition statements (ID, TYPE and RHS) in PROC LP:

proc lp;

id rowname;

type type;

rhs rhs;

run;

Other special variables for the dense format are _RHSSEN_ and _RANGE_, which identify the vectors for the right-hand-side sensitivity and range analyses. The corresponding statements are the

RHSSEN and RANGE statements. (Notice that a variable name can be identical to a statement name.)

In the same way, if you replace the variables _COL_, _ROW_, _TYPE_, and _COEF_ in the previous sparse form data set by COLUMN, ROW, TYPE, and COEF, you need the problem definition statements (COL, ROW, TYPE, and COEF) in PROC LP.

proc lp sparsedata;

col column;

row row;

type type;

coef coef;

run;

In the sparse form data set, the value '_RHS_' under the variable _COL_ is a special column name, which represents the model’s right-hand-side column. If you replace it by a value 'R', the PROC

LP statements would be

proc lp sparsedata;

rhs r;

run;

Other special column names for the sparse format are '_RHSSEN_' and '_RANGE_'. The corresponding statements are the RHSSEN and RANGE statements.

PROC LP is case insensitive to variable names and all character values, including the row and column names in the sparse format. The order of the problem definition statements is not important.

For the dense format, a model’s row names appear as character values in a SAS data set. For the sparse format, both the row and the column names of the model appear as character values in the data set. Thus, you can put spaces or other special characters in the names. When referring to these names in the problem definition statement or other LP statements, you must use single or double quotes around them. For example, if you replace '_RHS_' by 'R H S' in the previous sparse form data set, the PROC LP statements would become

proc lp sparsedata;

rhs "r h s";

run;

The specifications SPARSEDATA and DATA= in the previous examples are PROC LP options. PROC LP options include

Interactive control options include READPAUSE, ENDPAUSE, and so forth. You can run PROC LP interactively using those options. For example, for the blending problem example in the dense form, you can first pause the procedure before iterations start with the READPAUSE option. The PROC LP statements are

proc lp readpause; run;

When the procedure pauses, you run the PRINT statement to display the initial technological matrix and see if the input is correct. Then you run the PIVOT statement to do one simplex pivot and pause. After that you use the SHOW statement to check the current solution status. Then you apply the RESET statement to tell the procedure to stop as soon as it finds a solution. Now you use the RUN statement to continue the execution. When the procedure stops, you run the PRINT statement again to do a price range analysis and QUIT the procedure. Use a SAS %PUT statement to display the contents of PROC LP’s macro variable, _ORLP_, which contains iterations and solution information. What follows are the complete statements in batch mode:

proc lp readpause; run; print matrix(,); /* display all rows and columns. */ pivot; show status; reset endpause; run; print rangeprice; quit; %put &_orlp_;

Note: You can force PROC LP to pause during iterations by using the CTRL-BREAK key.