SCHART Statement: SHEWHART Procedure

Example 18.29 Specifying a Known Standard Deviation

Note: See s Chart with Known Standard Deviation in the SAS/QC Sample Library.

In some applications, a standard value  might be available for the process standard deviation

might be available for the process standard deviation  . This example shows how you can specify

. This example shows how you can specify  to compute the control limits.

to compute the control limits.

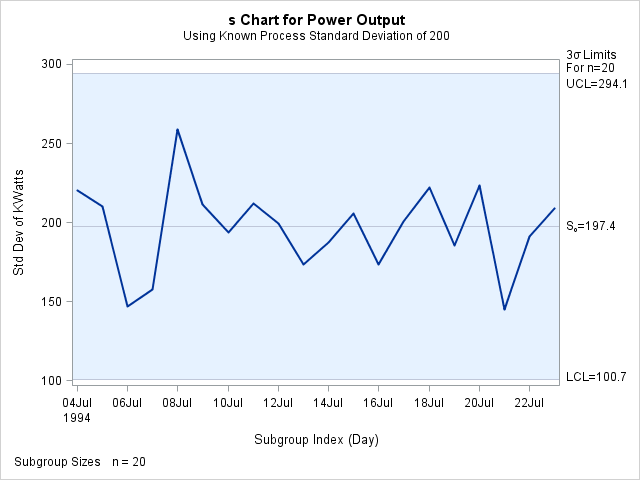

Suppose that the amount of power needed to heat water in the heating process described in Creating Standard Deviation Charts from Raw Data has a known standard deviation of 200. The following statements specify this known value and create an s chart, shown in Output 18.29.1, for the power output measurements in the data set Turbine:

ods graphics on;

title 's Chart for Power Output';

title2 'Using Known Process Standard Deviation of 200';

proc shewhart data=Turbine;

schart KWatts*Day / sigma0 = 200

ssymbol = s0

odstitle = title

odstitle2 = title2;

run;

The SIGMA0=

option specifies  , and the SSYMBOL=

option specifies a label for the central line indicating that the central line is computed from

, and the SSYMBOL=

option specifies a label for the central line indicating that the central line is computed from  . Because all the points lie within the limits, you can conclude that the variability of the process is stable.

. Because all the points lie within the limits, you can conclude that the variability of the process is stable.

Output 18.29.1: Reading in Standard Value for Process Standard Deviation

You can also specify  as the value of the variable

as the value of the variable _STDDEV_ in a LIMITS=

data set, as illustrated by the following statements:

data Plimits; length _var_ _subgrp_ _type_ $8; _var_ = 'KWatts'; _subgrp_ = 'Day'; _type_ = 'STDSIGMA'; _limitn_ = 20; _stddev_ = 200; run; title 'Chart Using Known Process Standard Deviation'; proc shewhart data=Turbine limits=Plimits; schart KWatts*Day / ssymbol=s0; run;

The resulting s chart (not shown here) is identical to the one shown in Output 18.29.1. For more information, see LIMITS= Data Set.