- Requesting Standard Tests

- Interpreting Standard Tests for Special Causes

- Modifying Standard Tests for Special Causes

- Applying Tests with Varying Subgroup Sample Sizes

- Labeling Signaled Points with a Variable

- Applying Tests with Multiple Phases

- Applying Tests with Multiple Sets of Control Limits

- Enhancing the Display of Signaled Tests

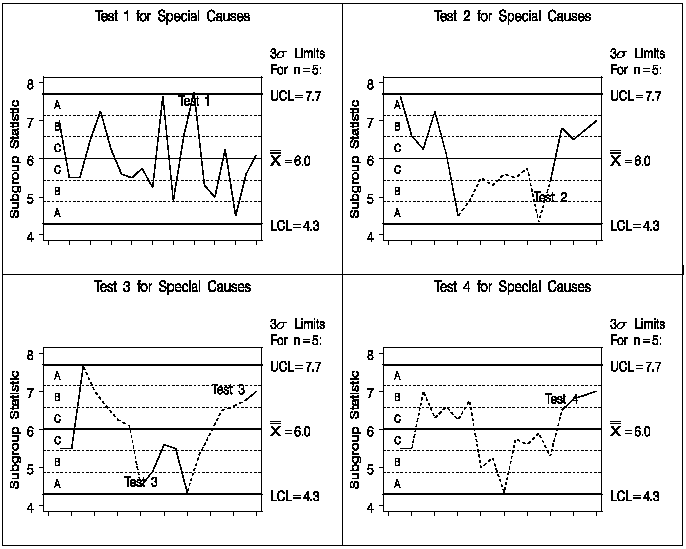

The SHEWHART procedure provides eight standard tests for special causes, also referred to as rules for lack of control, supplementary rules, runs tests, runs rules, pattern tests, and Western Electric rules. These tests improve the sensitivity of the Shewhart chart to small changes in the process. [41] You can also improve the sensitivity of the chart by increasing the rate of sampling, increasing the subgroup sample size, and using control limits that represent less than three standard errors of variation from the central line. However, increasing the sampling rate and sample size is often impractical, and tightening the control limits increases the chances of falsely signaling an out-of-control condition. By detecting particular nonrandom patterns in the points plotted on the chart, the tests can provide greater sensitivity and useful diagnostic information while incurring a reasonable probability of a false signal.

The patterns detected by the eight standard tests are defined in Table 17.94 and Table 17.95, and they are illustrated in Figure 17.177 and Figure 17.178. All eight tests were developed for use with fixed ![]() limits. The tests are indexed according to the numbering sequence used by Nelson (1984, 1985). You can request any combination of the eight tests by specifying the test indexes with the TESTS= option in the BOXCHART, CCHART, IRCHART, MCHART, MRCHART, NPCHART, PCHART, UCHART, XCHART, XRCHART, and XSCHART

statements.

limits. The tests are indexed according to the numbering sequence used by Nelson (1984, 1985). You can request any combination of the eight tests by specifying the test indexes with the TESTS= option in the BOXCHART, CCHART, IRCHART, MCHART, MRCHART, NPCHART, PCHART, UCHART, XCHART, XRCHART, and XSCHART

statements.

The following restrictions apply to the tests:

-

Only Tests 1, 2, 3, and 4 are recommended for c charts,

charts, p charts, and u charts created with the CCHART, NPCHART, PCHART, and UCHART statements, respectively. In these four cases, Test 2 should

not be used unless the process distribution is symmetric or nearly symmetric.

charts, p charts, and u charts created with the CCHART, NPCHART, PCHART, and UCHART statements, respectively. In these four cases, Test 2 should

not be used unless the process distribution is symmetric or nearly symmetric.

-

By default, the TESTS= option is not applied with control limits that are not

limits or that vary with subgroup sample size. You can use the NO3SIGMACHECK option to request tests for special causes when

the SIGMAS= option specifies control limits other than

limits or that vary with subgroup sample size. You can use the NO3SIGMACHECK option to request tests for special causes when

the SIGMAS= option specifies control limits other than  limits. This is not recommended for standard control chart applications, since the standard tests for special causes are

based on

limits. This is not recommended for standard control chart applications, since the standard tests for special causes are

based on  limits. You can apply tests for special causes when control limits vary with subgroup sample size by using the LIMITN= or

TESTNMETHOD= options (see Requesting Standard Tests and Applying Tests with Varying Subgroup Sample Sizes).

limits. You can apply tests for special causes when control limits vary with subgroup sample size by using the LIMITN= or

TESTNMETHOD= options (see Requesting Standard Tests and Applying Tests with Varying Subgroup Sample Sizes).

Table 17.94: Definitions of Tests 1 to 4

|

Test Index |

Pattern Description |

|---|---|

|

1 |

One point beyond Zone A (outside the control limits) |

|

2 |

Nine points in a row in Zone C or beyond on one side of the central line (see Note 1 below) |

|

3 |

Six points in a row steadily increasing or steadily decreasing (see Note 2 below) |

|

4 |

Fourteen points in a row alternating up and down |

Notes:

-

The number of points in Test 2 can be specified as 7, 8, 9, 11, 14, or 20 with the TEST2RUN= option.

-

The number of points in Test 3 can be specified as 6, 7, or 8 with the TEST3RUN= option.

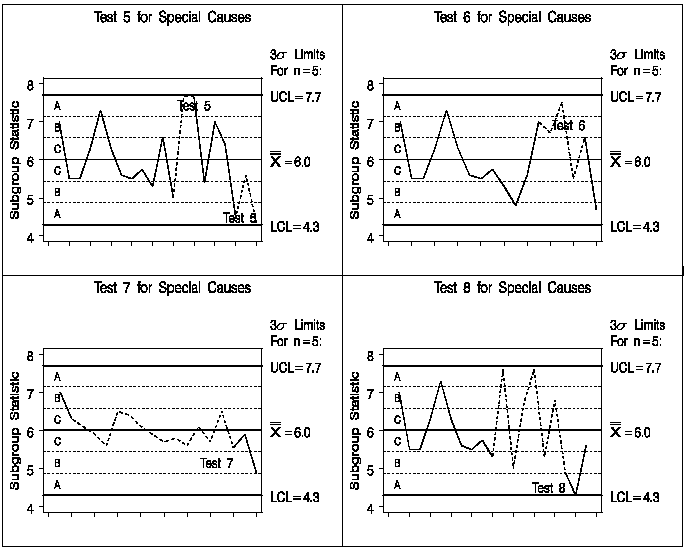

Table 17.95: Definitions of Tests 5 to 8

|

Test Index |

Pattern Description |

|---|---|

|

5 |

Two out of three points in a row in Zone A or beyond |

|

6 |

Four out of five points in a row in Zone B or beyond |

|

7 |

Fifteen points in a row in Zone C on either or both sides of the central line |

|

8 |

Eight points in a row on either or both sides of the central line with no points in Zone C |

[41] Cumulative sum control charts and moving average control charts also detect small shifts more quickly than an ordinary Shewhart chart. See the sections PROC CUSUM Statement and PROC MACONTROL Statement for more information.