XRCHART Statement: SHEWHART Procedure

Note: See X-bar and R CHARTS-Specifying Standard Values in the SAS/QC Sample Library.

By default, the XRCHART statement estimates the process mean (![]() ) and standard deviation (

) and standard deviation (![]() ) from the data, as in the previous example. However, there are applications in which standard values (

) from the data, as in the previous example. However, there are applications in which standard values (![]() and

and ![]() ) are available based, for instance, on previous experience or extensive sampling. You can specify these values with the MU0=

and SIGMA0= options.

) are available based, for instance, on previous experience or extensive sampling. You can specify these values with the MU0=

and SIGMA0= options.

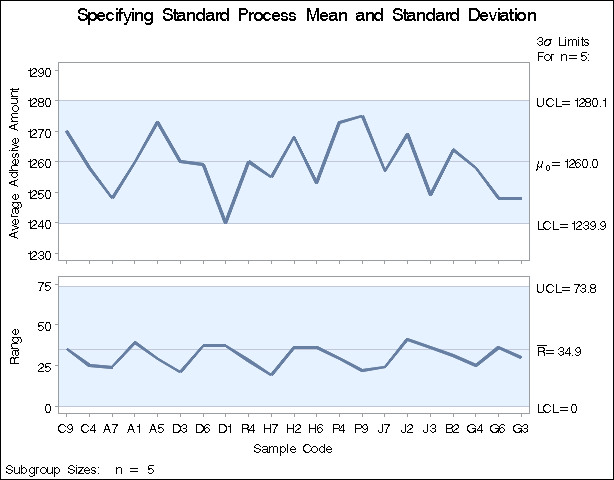

For example, suppose it is known that the adhesive coating process introduced in the previous example has a mean of 1260 and standard deviation of 15. The following statements specify these standard values:

ods graphics off;

title 'Specifying Standard Process Mean and Standard Deviation';

proc shewhart history=Tape;

xrchart Weight*Sample / mu0 = 1260

sigma0 = 15

xsymbol = mu0;

run;

The XSYMBOL= option specifies the label for the central line on the ![]() chart. The resulting

chart. The resulting ![]() and R charts are shown in Output 17.39.1.

and R charts are shown in Output 17.39.1.

The central lines and control limits for both charts are determined by using ![]() and

and ![]() (see the equations in Table 17.72). Output 17.39.1 indicates that the process is in statistical control.

(see the equations in Table 17.72). Output 17.39.1 indicates that the process is in statistical control.

You can also specify ![]() and

and ![]() with the variables

with the variables _MEAN_ and _STDDEV_ in a LIMITS= data set, as illustrated by the following statements:

data Tapelim; length _var_ _subgrp_ _type_ $8; _var_ = 'Weight'; _subgrp_ = 'Sample'; _type_ = 'STANDARD'; _limitn_ = 5; _mean_ = 1260; _stddev_ = 15; proc shewhart history=Tape limits=Tapelim; xrchart Weight*Sample / xsymbol=mu0; run;

The variables _VAR_ and _SUBGRP_ are required, and their values must match the process and subgroup-variable, respectively, specified in the XRCHART statement. The bookkeeping variable _TYPE_ is not required, but it is recommended to indicate that the variables _MEAN_ and _STDDEV_ provide standard values rather than estimated values.

The resulting charts (not shown here) are identical to those shown in Output 17.39.1.