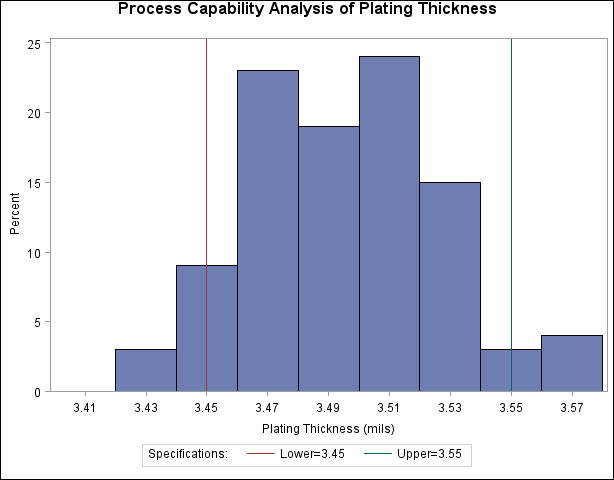

HISTOGRAM Statement: CAPABILITY Procedure

See CAPHST1 in the SAS/QC Sample LibraryA semiconductor manufacturer produces printed circuit boards that are sampled to determine whether the thickness of their

copper plating lies between a lower specification limit of 3.45 mils and an upper specification limit of 3.55 mils. The plating

process is assumed to be in statistical control. The plating thicknesses of 100 boards are saved in a data set named Trans, created by the following statements:

data Trans; input Thick @@; label Thick='Plating Thickness (mils)'; datalines; 3.468 3.428 3.509 3.516 3.461 3.492 3.478 3.556 3.482 3.512 3.490 3.467 3.498 3.519 3.504 3.469 3.497 3.495 3.518 3.523 3.458 3.478 3.443 3.500 3.449 3.525 3.461 3.489 3.514 3.470 3.561 3.506 3.444 3.479 3.524 3.531 3.501 3.495 3.443 3.458 3.481 3.497 3.461 3.513 3.528 3.496 3.533 3.450 3.516 3.476 3.512 3.550 3.441 3.541 3.569 3.531 3.468 3.564 3.522 3.520 3.505 3.523 3.475 3.470 3.457 3.536 3.528 3.477 3.536 3.491 3.510 3.461 3.431 3.502 3.491 3.506 3.439 3.513 3.496 3.539 3.469 3.481 3.515 3.535 3.460 3.575 3.488 3.515 3.484 3.482 3.517 3.483 3.467 3.467 3.502 3.471 3.516 3.474 3.500 3.466 ;

The following statements create the histogram shown in Figure 5.8:

ods graphics off; title 'Process Capability Analysis of Plating Thickness'; legend2 frame; proc capability data=Trans noprint; spec lsl = 3.45 usl = 3.55; histogram Thick / legend = legend2; run;

A histogram is created for each variable listed after the keyword HISTOGRAM. The SPEC statement, which is optional, provides the specification limits that are displayed on the histogram. For more information about the SPEC statement, see SPEC Statement.

The NOPRINT option suppresses printed output with summary statistics for the variable Thick that would be displayed by default. See Computing Descriptive Statistics for an example of this output.