Preliminary Examination of Variation

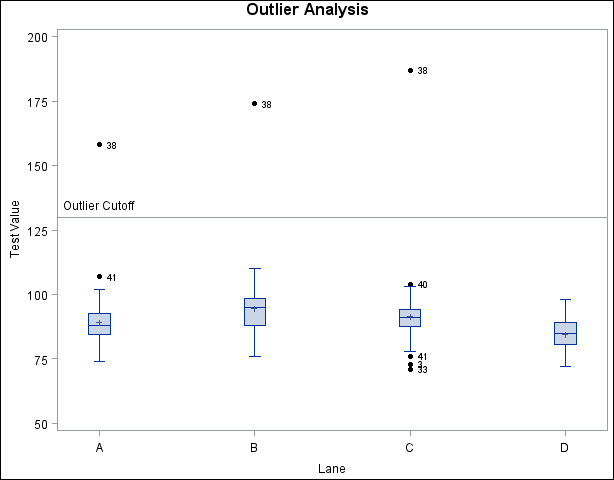

As a preliminary step in the analysis, the data are sorted by lane and visually screened for outliers (test values greater than 130) with box plots created as follows:

proc sort data=Film;

by Lane;

run;

symbol h = 2.0 pct;

title 'Outlier Analysis';

proc shewhart data=Film;

boxchart Testval*Lane / boxstyle = schematicid

idsymbol = dot

vref = 130

vreflab = 'Outlier Cutoff'

hoffset = 5

nolegend

stddevs

nolimits ;

id Sample;

run;

Specifying BOXSTYLE=SCHEMATICID requests schematic box plots with outliers identified by the value of the ID variable Sample. The STDDEVS option specifies that the estimate of the process standard deviation is to be based on subgroup standard deviations. Although this estimate is not needed here because control limits are not displayed, it is recommended that you specify the STDDEVS option whenever you are working with subgroup sample sizes greater than ten. The NOLEGEND and NOLIMITS options suppress the subgroup sample size legend and control limits for lane means that are displayed by default. The display is shown in Figure 15.200.

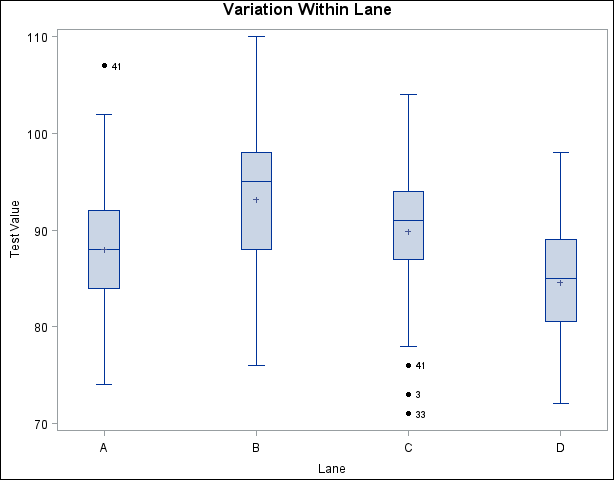

Figure 15.201 shows similarly created box plots for the data in Film2, which is created by removing the outliers from the data set Film.

data Film2;

set Film;

if Testval < 130;

symbol h = 2.0 pct;

title 'Variation Within Lane';

proc shewhart data=Film2;

boxchart Testval*Lane / boxstyle = schematicid

boxwidth = 5

idsymbol = dot

hoffset = 5

nolegend

stddevs

nolimits ;

id Sample;

run;

Since you have no additional information about the process, you may want to create a conventional  and

and  chart for the test values grouped by the variable Sample. This is a straightforward application of the XRCHART statement in the SHEWHART procedure.

chart for the test values grouped by the variable Sample. This is a straightforward application of the XRCHART statement in the SHEWHART procedure.

proc sort data=Film2;

by Sample;

run;

symbol h=2.0 pct;

title 'Shewhart Chart for Means and Ranges';

proc shewhart data=Film2;

xrchart Testval*Sample /

split = '/'

npanelpos = 60

limitn = 4

outlimits = RLimits

nolegend

alln;

label Testval='Average Test Value/Range';

run;

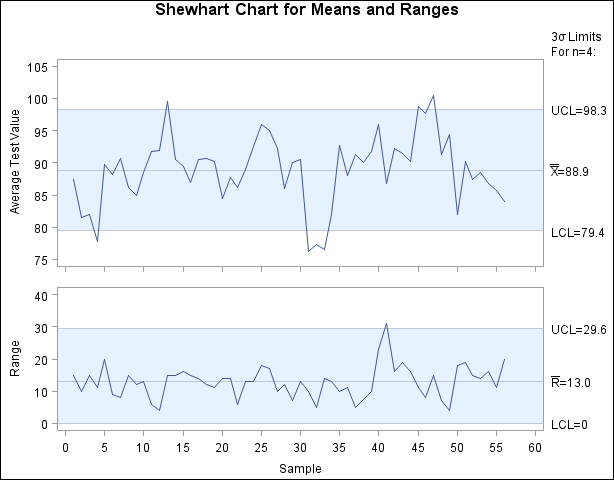

The  and

and  chart is displayed in Figure 15.202. Ordinarily, the out-of-control points in the

chart is displayed in Figure 15.202. Ordinarily, the out-of-control points in the  chart would indicate that the process is not in statistical control. In this situation, however, the process is known to be quite stable, and the data have been screened for outliers. The problem is that the control limits for the average test value were computed from an inappropriate model. This is discussed in the following section.

chart would indicate that the process is not in statistical control. In this situation, however, the process is known to be quite stable, and the data have been screened for outliers. The problem is that the control limits for the average test value were computed from an inappropriate model. This is discussed in the following section.

and

and  Chart

Chart