PROC CAPABILITY and General Statements

Standard Capability Indices

This section provides computational details for the standard process capability indices computed by the CAPABILITY procedure:  , CPL, CPU,

, CPL, CPU,  , and

, and  .

.

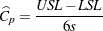

The Index Cp

The process capability index  , sometimes called the "process potential index," the "process capability ratio," or the "inherent capability index," is estimated as

, sometimes called the "process potential index," the "process capability ratio," or the "inherent capability index," is estimated as

|

where USL is the upper specification limit, LSL is the lower specification limit, and  is the sample standard deviation. If you do not specify both the upper and the lower specification limits in the SPEC statement or the SPEC= data set, then

is the sample standard deviation. If you do not specify both the upper and the lower specification limits in the SPEC statement or the SPEC= data set, then  is assigned a missing value.

is assigned a missing value.

The interpretation of  can depend on the application, on past experience, and on local practice. However, broad guidelines for interpretation have been proposed by several authors. Ekvall and Juran (1974) classify

can depend on the application, on past experience, and on local practice. However, broad guidelines for interpretation have been proposed by several authors. Ekvall and Juran (1974) classify  values as

values as

"not adequate" if

"adequate" if

, but requiring close control as

, but requiring close control as  approaches 1

approaches 1 "more than adequate" if

Montgomery (1996) recommends minimum values of  as

as

1.33 for existing processes

1.50 for new processes or for existing processes when the variable is critical (for example, related to safety or strength)

1.67 for new processes when the variable is critical

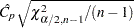

Exact  lower and upper confidence limits for

lower and upper confidence limits for  (denoted by LCL and UCL) are computed using percentiles of the chi-square distribution, as indicated by the following equations:

(denoted by LCL and UCL) are computed using percentiles of the chi-square distribution, as indicated by the following equations:

|

|

|

|||

|

|

|

Here,  denotes the lower

denotes the lower  th percentile of the chi-square distribution with

th percentile of the chi-square distribution with  degrees of freedom. Refer to Chou, Owen, and Borrego (1990) and Kushler and Hurley (1992).

degrees of freedom. Refer to Chou, Owen, and Borrego (1990) and Kushler and Hurley (1992).

You can specify  with the ALPHA= option in the PROC CAPABILITY statement or with the CIINDICES( ALPHA=value ) in the PROC CAPABILITY statement. The default value is 0.05. You can save these limits in the OUT= data set by specifying the keywords CPLCL and CPUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying the keywords in the INSET statement.

with the ALPHA= option in the PROC CAPABILITY statement or with the CIINDICES( ALPHA=value ) in the PROC CAPABILITY statement. The default value is 0.05. You can save these limits in the OUT= data set by specifying the keywords CPLCL and CPUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying the keywords in the INSET statement.

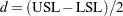

The Index CPL

The process capability index CPL is estimated as

|

where  is the sample mean, LSL is the lower specification limit, and

is the sample mean, LSL is the lower specification limit, and  is the sample standard deviation. If you do not specify the lower specification limit in the SPEC statement or the SPEC= data set, then CPL is assigned a missing value.

is the sample standard deviation. If you do not specify the lower specification limit in the SPEC statement or the SPEC= data set, then CPL is assigned a missing value.

Montgomery (1996) refers to CPL as the "process capability ratio" in the case of one-sided lower specifications and recommends minimum values as follows:

1.25 for existing processes

1.45 for new processes or for existing processes when the variable is critical

1.60 for new processes when the variable is critical

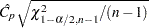

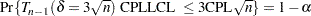

Exact  lower and upper confidence limits for CPL are computed using a generalization of the method of Chou, Owen, and Borrego (1990), who point out that the

lower and upper confidence limits for CPL are computed using a generalization of the method of Chou, Owen, and Borrego (1990), who point out that the  lower confidence limit for CPL (denoted by CPLLCL )satisfies the equation

lower confidence limit for CPL (denoted by CPLLCL )satisfies the equation

|

where  has a non-central

has a non-central  distribution with

distribution with  degrees of freedom and noncentrality parameter

degrees of freedom and noncentrality parameter  . You can specify

. You can specify  with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. The confidence limits can be saved in an output data set by specifying the keywords CPLLCL and CPLUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these keywords in the INSET statement.

with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. The confidence limits can be saved in an output data set by specifying the keywords CPLLCL and CPLUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these keywords in the INSET statement.

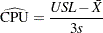

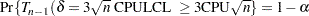

The Index CPU

The process capability index CPU is estimated as

|

where USL is the upper specification limit,  is the sample mean, and

is the sample mean, and  is the sample standard deviation. If you do not specify the upper specification limit in the SPEC statement or the SPEC= data set, then CPU is assigned a missing value.

is the sample standard deviation. If you do not specify the upper specification limit in the SPEC statement or the SPEC= data set, then CPU is assigned a missing value.

Montgomery (1996) refers to CPU as the "process capability ratio" in the case of one-sided upper specifications and recommends minimum values that are the same as those specified previously for CPL.

Exact  lower and upper confidence limits for CPU are computed using a generalization of the method of Chou, Owen, and Borrego (1990), who point out that the

lower and upper confidence limits for CPU are computed using a generalization of the method of Chou, Owen, and Borrego (1990), who point out that the  lower confidence limit for CPU (denoted by CPULCL )satisfies the equation

lower confidence limit for CPU (denoted by CPULCL )satisfies the equation

|

where  has a non-central

has a non-central  distribution with

distribution with  degrees of freedom and noncentrality parameter

degrees of freedom and noncentrality parameter  . You can specify

. You can specify  with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. The confidence limits can be saved in an output data set by specifying the keywords CPULCL and CPUUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these keywords in the INSET statement.

with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. The confidence limits can be saved in an output data set by specifying the keywords CPULCL and CPUUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these keywords in the INSET statement.

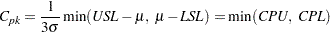

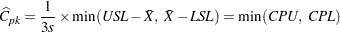

The Index Cpk

The process capability index  is defined as

is defined as

|

Note that the indices  ,

,  , and

, and  are related as

are related as  . The CAPABILITY procedure estimates

. The CAPABILITY procedure estimates  as

as

|

where USL is the upper specification limit, LSL is the lower specification limit,  is the sample mean, and

is the sample mean, and  is the sample standard deviation.

is the sample standard deviation.

If you specify only the upper limit in the SPEC statement or the SPEC= data set, then  is computed as CPU, and if you specify only the lower limit in the SPEC statement or the SPEC= data set, then

is computed as CPU, and if you specify only the lower limit in the SPEC statement or the SPEC= data set, then  is computed as CPL.

is computed as CPL.

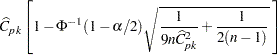

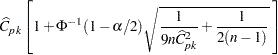

Bissell (1990) derived approximate two-sided 95% confidence limits for  by assuming that the distribution of

by assuming that the distribution of  is normal. Using Bissell’s approach, 100

is normal. Using Bissell’s approach, 100 % lower and upper confidence limits can be computed as

% lower and upper confidence limits can be computed as

|

|

|

|||

|

|

|

where  denotes the cumulative standard normal distribution function. Kushler and Hurley (1992) concluded that Bissell’s method gives reasonably accurate results.

denotes the cumulative standard normal distribution function. Kushler and Hurley (1992) concluded that Bissell’s method gives reasonably accurate results.

You can specify  with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. These limits can be saved in an output data set by specifying the keywords CPKLCL and CPKUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these same keywords in the INSET statement.

with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. These limits can be saved in an output data set by specifying the keywords CPKLCL and CPKUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these same keywords in the INSET statement.

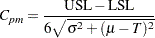

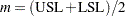

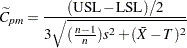

The Index Cpm

The process capability index  is intended to account for deviation from the target

is intended to account for deviation from the target  in addition to variability from the mean. This index is often defined as

in addition to variability from the mean. This index is often defined as

|

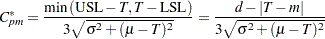

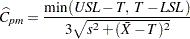

A closely related version of  is the index

is the index

|

where  and

and  . If

. If  , then

, then  . However, if

. However, if  , then both indices suffer from problems of interpretation, as pointed out by Kotz and Johnson (1993), and their use should be avoided in this case.

, then both indices suffer from problems of interpretation, as pointed out by Kotz and Johnson (1993), and their use should be avoided in this case.

The CAPABILITY procedure computes an estimator of  as

as

|

where  is the sample standard deviation.

is the sample standard deviation.

If you specify only a single specification limit SL in the SPEC statement or the SPEC= data set, then  is estimated as

is estimated as

|

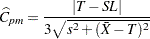

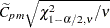

Boyles (1991) proposed a slightly modified point estimate for  computed as

computed as

|

Boyles also suggested approximate two-sided 100 % confidence limits for

% confidence limits for  , which are computed as

, which are computed as

|

|

|

|||

|

|

|

Here  denotes the lower

denotes the lower  th percentile of the chi-square distribution with

th percentile of the chi-square distribution with  degrees of freedom, where

degrees of freedom, where  equals

equals

|

You can specify  with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. These confidence limits can be saved in an output data set by specifying the keywords CPMLCL and CPMUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these keywords in the INSET statement.

with the ALPHA= option in the PROC CAPABILITY statement. The default value is 0.05. These confidence limits can be saved in an output data set by specifying the keywords CPMLCL and CPMUCL in the OUTPUT statement. In addition, you can display these limits on plots produced by the CAPABILITY procedure by specifying these keywords in the INSET statement.