| Nonlinear Optimization Examples |

Example 11.3: Compartmental Analysis

Numerical Considerations

An important class of nonlinear models involves a dynamic description of the response rather than an explicit description. These models arise often in chemical kinetics, pharmacokinetics, and ecological compartmental modeling. Two examples are presented in this section. Refer to Bates and Watts (1988) for a more general introduction to the topic.In this class of problems, function evaluations, as well as gradient evaluations, are not done in full precision. Evaluating a function involves the numerical solution of a differential equation with some prescribed precision. Therefore, two choices exist for evaluating first- and second-order derivatives:

- differential equation approach

- finite-difference approach

With the finite-difference approach, a very delicate balance of all the precision requirements of every routine must exist. In the examples that follow, notice the relative levels of precision that are imposed on different modules. Since finite differences are used to compute the first- and second-order derivatives, it is incorrect to set the precision of the ODE solver at a coarse level because that would render the numerical estimation of the finite differences worthless.

A coarse computation of the solution of the differential equation cannot be accompanied by very fine computation of the finite-difference estimates of the gradient and the Hessian. That is, you cannot set the precision of the differential equation solver to be 1E-4 and perform the finite difference estimation with a precision of 1E-10. In addition, this precision must be well-balanced with the termination criteria imposed on the optimization process.

In general, if the precision of the function evaluation is

![]() , the gradient should be computed by finite

differences

, the gradient should be computed by finite

differences ![]() , and the Hessian should be

computed with finite differences

, and the Hessian should be

computed with finite differences ![]() .

*

.

*

Diffusion of Tetracycline

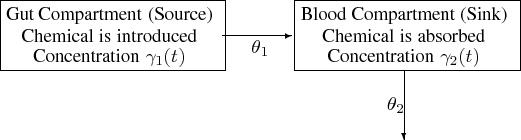

Consider the concentration of tetracycline hydrochloride in blood serum. The tetracycline is administered to a subject orally, and the concentration of the tetracycline in the serum is measured. The biological system to be modeled consists of two compartments: a gut compartment in which tetracycline is injected and a blood compartment that absorbs the tetracycline from the gut compartment for delivery to the body. Let

The rates of flow of the drug are described by the following pair of ordinary differential equations:

Also, a nonnegativity constraint is imposed on the

parameters ![]() ,

, ![]() , and

, and ![]() , although

for numerical purposes, you might need to use a small

value instead of zero for these bounds (such as 1E-7).

, although

for numerical purposes, you might need to use a small

value instead of zero for these bounds (such as 1E-7).

Suppose ![]() is the observed serum concentration at time

is the observed serum concentration at time ![]() .

The parameters are estimated by minimizing the

sum of squares of the differences between the

observed and predicted serum concentrations:

.

The parameters are estimated by minimizing the

sum of squares of the differences between the

observed and predicted serum concentrations:

data tetra;

input t c @@;

datalines;

1 0.7 2 1.2 3 1.4 4 1.4 6 1.1

8 0.8 10 0.6 12 0.5 16 0.3

;

proc iml;

use tetra;

read all into tetra;

start f(theta) global(thmtrx,t,h,tetra,eps);

thmtrx = ( -theta[1] || 0 ) //

( theta[1] || -theta[2] );

c = theta[3]//0 ;

t = 0 // tetra[,1];

call ode( r1, "der",c , t, h) j="jac" eps=eps;

f = ssq((r1[2,])`-tetra[,2]);

return(f);

finish;

start der(t,x) global(thmtrx);

y = thmtrx*x;

return(y);

finish;

start jac(t,x) global(thmtrx);

y = thmtrx;

return(y);

finish;

h = {1.e-14 1. 1.e-5};

opt = {0 2 0 1 };

tc = repeat(.,1,12);

tc[1] = 100;

tc[7] = 1.e-8;

par = { 1.e-13 . 1.e-10 . . . . };

con = j(1,3,0.);

itheta = { .1 .3 10};

eps = 1.e-11;

call nlpdd(rc,rx,"f",itheta) blc=con opt=opt tc=tc par=par;

The output from the optimization process is shown in Output 11.3.1.

Output 11.3.1: (continued)

|

| Optimization Results | |||

| Iterations | 32 | Function Calls | 46 |

| Gradient Calls | 34 | Active Constraints | 0 |

| Objective Function | 0.0356522978 | Max Abs Gradient Element | 0.0008005458 |

| Slope of Search Direction | -2.999826E-8 | Radius | 1 |

| FCONV convergence criterion satisfied. |

| Optimization Results | |||

| Parameter Estimates | |||

| N | Parameter | Estimate | Gradient Objective Function |

| 1 | X1 | 0.181807 | 0.000388 |

| 2 | X2 | 0.437717 | 0.000801 |

| 3 | X3 | 6.048279 | 0.000239 |

| Value of Objective Function = 0.0356522978 |

The differential equation model is linear, and in fact, it can be solved by using an eigenvalue decomposition (this is not always feasible without complex arithmetic). Alternately, the availability and the simplicity of the closed form representation of the solution enable you to replace the solution produced by the ODE routine with the simpler and faster analytical solution. Closed forms are not expected to be easily available for nonlinear systems of differential equations, which is why the preceding solution was introduced.

The closed form of the solution requires

a change to the function ![]() .

The functions needed as arguments of the ODE routine,

namely the der and jac modules, can be removed.

Here is the revised code:

.

The functions needed as arguments of the ODE routine,

namely the der and jac modules, can be removed.

Here is the revised code:

start f(th) global(theta,tetra);

theta = th;

vv = v(tetra[,1]);

error = ssq(vv-tetra[,2]);

return(error);

finish;

start v(t) global(theta);

v = theta[3]*theta[1]/(theta[2]-theta[1])*

(exp(-theta[1]*t)-exp(-theta[2]*t));

return(v);

finish;

call nlpdd(rc,rx,"f",itheta) blc=con opt=opt tc=tc par=par;

The parameter estimates, which are shown in Output 11.3.2, are close to those obtained by the first solution.

Output 11.3.2: Second Set of Parameter Estimates for Tetracycline Diffusion

|

| Optimization Results | |||

| Parameter Estimates | |||

| N | Parameter | Estimate | Gradient Objective Function |

| 1 | X1 | 0.183025 | -0.000003196 |

| 2 | X2 | 0.434482 | 0.000002274 |

| 3 | X3 | 5.995241 | -0.000001035 |

| Value of Objective Function = 0.0356467763 |

Because of the nature of the closed form of the solution, you

might want to add an additional constraint to guarantee that

![]() at any time during the optimization.

This prevents a possible division by or a value

near in the execution of the

at any time during the optimization.

This prevents a possible division by or a value

near in the execution of the ![]() function.

For example, you might add the constraint

function.

For example, you might add the constraint

Chemical Kinetics of Pyrolysis of Oil Shale

Pyrolysis is a chemical change effected by the action of heat, and this example considers the pyrolysis of oil shale described in Ziegel and Gorman (1980). Oil shale contains organic material that is bonded to the rock. To extract oil from the rock, heat is applied, and the organic material is decomposed into oil, bitumen, and other byproducts. The model is given by

data oil ( drop=temp);

input temp time bitumen oil;

datalines;

673 5 0. 0.

673 7 2.2 0.

673 10 11.5 0.7

673 15 13.7 7.2

673 20 15.1 11.5

673 25 17.3 15.8

673 30 17.3 20.9

673 40 20.1 26.6

673 50 20.1 32.4

673 60 22.3 38.1

673 80 20.9 43.2

673 100 11.5 49.6

673 120 6.5 51.8

673 150 3.6 54.7

;

proc iml;

use oil;

read all into a;

/****************************************************************/

/* The INS function inserts a value given by FROM into a vector */

/* given by INTO, sorts the result, and posts the global matrix */

/* that can be used to delete the effects of the point FROM. */

/****************************************************************/

start ins(from,into) global(permm);

in = into // from;

x = i(nrow(in));

permm = inv(x[rank(in),]);

return(permm*in);

finish;

start der(t,x) global(thmtrx,thet);

y = thmtrx*x;

if ( t <= thet[5] ) then y = 0*y;

return(y);

finish;

start jac(t,x) global(thmtrx,thet);

y = thmtrx;

if ( t <= thet[5] ) then y = 0*y;

return(y);

finish;

start f(theta) global(thmtrx,thet,time,h,a,eps,permm);

thet = theta;

thmtrx = (-(theta[1]+theta[4]) || 0 || 0 )//

(theta[1] || -(theta[2]+theta[3]) || 0 )//

(theta[4] || theta[2] || 0 );

t = ins( theta[5],time);

c = { 100, 0, 0};

call ode( r1, "der",c , t , h) j="jac" eps=eps;

/* send the intermediate value to the last column */

r = (c ||r1) * permm;

m = r[2:3,(2:nrow(time))];

mm = m`- a[,2:3];

call qr(q,r,piv,lindep,mm);

v = det(r);

return(abs(v));

finish;

opt = {0 2 0 1 };

tc = repeat(.,1,12);

tc[1] = 100;

tc[7] = 1.e-7;

par = { 1.e-13 . 1.e-10 . . . .};

con = j(1,5,0.);

h = {1.e-14 1. 1.e-5};

time = (0 // a[,1]);

eps = 1.e-5;

itheta = { 1.e-3 1.e-3 1.e-3 1.e-3 1.};

call nlpqn(rc,rx,"f",itheta) blc=con opt=opt tc=tc par=par;

The parameter estimates are shown in Output 11.3.3.

Output 11.3.3: Parameter Estimates for Oil Shale Pyrolysis

| |||||||||||||||||||||||||||||||||

Again, compare the solution using the approximation produced by the ODE subroutine to the solution obtained through the closed form of the given differential equation. Impose the following additional constraint to avoid a possible division by when evaluating the function:

start f(thet) global(time,a);

do i = 1 to nrow(time);

t = time[i];

v1 = 100;

if ( t >= thet[5] ) then

v1 = 100*ev(t,thet[1],thet[4],thet[5]);

v2 = 0;

if ( t >= thet[5] ) then

v2 = 100*thet[1]/(thet[2]+thet[3]-thet[1]-thet[4])*

(ev(t,thet[1],thet[4],thet[5])-

ev(t,thet[2],thet[3],thet[5]));

v3 = 0;

if ( t >= thet[5] ) then

v3 = 100*thet[4]/(thet[1]+thet[4])*

(1. - ev(t,thet[1],thet[4],thet[5])) +

100*thet[1]*thet[2]/(thet[2]+thet[3]-thet[1]-thet[4])*(

(1.-ev(t,thet[1],thet[4],thet[5]))/(thet[1]+thet[4]) -

(1.-ev(t,thet[2],thet[3],thet[5]))/(thet[2]+thet[3]) );

y = y // (v1 || v2 || v3);

end;

mm = y[,2:3]-a[,2:3];

call qr(q,r,piv,lindep,mm);

v = det(r);

return(abs(v));

finish;

start ev(t,a,b,c);

return(exp(-(a+b)*(t-c)));

finish;

con = { 0. 0. 0. 0. . . . ,

. . . . . . . ,

-1 1 1 -1 . 1 1.e-7 };

time = a[,1];

par = { 1.e-13 . 1.e-10 . . . .};

itheta = { 1.e-3 1.e-3 1.e-2 1.e-3 1.};

call nlpqn(rc,rx,"f",itheta) blc=con opt=opt tc=tc par=par;

The parameter estimates are shown in Output 11.3.4.

Output 11.3.4: Second Set of Parameter Estimates for Oil Shale Pyrolysis

| |||||||||||||||||||||||||||||||||

Copyright © 2009 by SAS Institute Inc., Cary, NC, USA. All rights reserved.

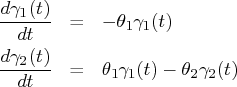

![\frac{d\gamma_1(t)}{dt} & = & -(\theta_1+\theta_4) \gamma_1(t) \iota(t,\theta_... ...t)}{dt} & = & [\theta_4 \gamma_1(t) + \theta_2 \gamma_2(t)] \iota(t,\theta_5)](images/nonlinearoptexpls_nonlinearoptexplseq292.gif)