The SSM Procedure

-

Overview

- Getting Started

-

Syntax

-

Details

State Space Model and NotationTypes of Sequence DataOverview of Model Specification SyntaxFiltering, Smoothing, Likelihood, and Structural Break DetectionEstimation of User-Specified Linear Combination of State ElementsContrasting PROC SSM with Other SAS Procedures Predefined Trend ModelsPredefined Structural ModelsCovariance ParameterizationMissing ValuesComputational IssuesDisplayed OutputODS Table NamesODS Graph NamesOUT= Data Set

State Space Model and NotationTypes of Sequence DataOverview of Model Specification SyntaxFiltering, Smoothing, Likelihood, and Structural Break DetectionEstimation of User-Specified Linear Combination of State ElementsContrasting PROC SSM with Other SAS Procedures Predefined Trend ModelsPredefined Structural ModelsCovariance ParameterizationMissing ValuesComputational IssuesDisplayed OutputODS Table NamesODS Graph NamesOUT= Data Set -

Examples

Bivariate Basic Structural Model Panel Data: Two-Way Random-Effects and Autoregressive ModelsBackcasting, Forecasting, and InterpolationLongitudinal Data: Smoothing of Repeated MeasuresA User-Defined Trend ModelModel with Multiple ARIMA ComponentsDynamic Factor ModelingDiagnostic Plots and Structural Break AnalysisLongitudinal Data: Variable Bandwidth SmoothingA Transfer Function Model for the Gas Furnace DataPanel Data: Dynamic Panel Model for the Cigar DataMultivariate Modeling: Analysis of Long-Term Temperature Trends

Bivariate Basic Structural Model Panel Data: Two-Way Random-Effects and Autoregressive ModelsBackcasting, Forecasting, and InterpolationLongitudinal Data: Smoothing of Repeated MeasuresA User-Defined Trend ModelModel with Multiple ARIMA ComponentsDynamic Factor ModelingDiagnostic Plots and Structural Break AnalysisLongitudinal Data: Variable Bandwidth SmoothingA Transfer Function Model for the Gas Furnace DataPanel Data: Dynamic Panel Model for the Cigar DataMultivariate Modeling: Analysis of Long-Term Temperature Trends - References

This example provides information about the diagnostic plots that the SSM procedure produces. In addition, a simple illustration of structural break analysis is also provided. The following plots are available in the SSM procedure:

-

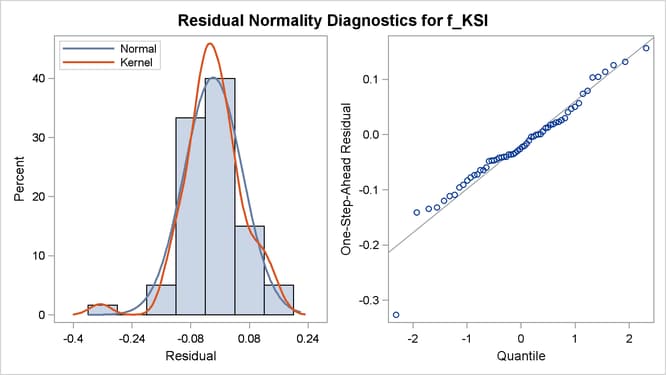

a panel of two plots—a histogram and a Q-Q plot—for the normality check of the one-step-ahead residuals

. A separate panel is produced for each response variable.

. A separate panel is produced for each response variable.

-

a time series plot of standardized residuals, one per response variable

-

a panel of two plots—a histogram and a Q-Q plot—for the normality check of the prediction errors

. A separate panel is produced for each response variable.

. A separate panel is produced for each response variable.

-

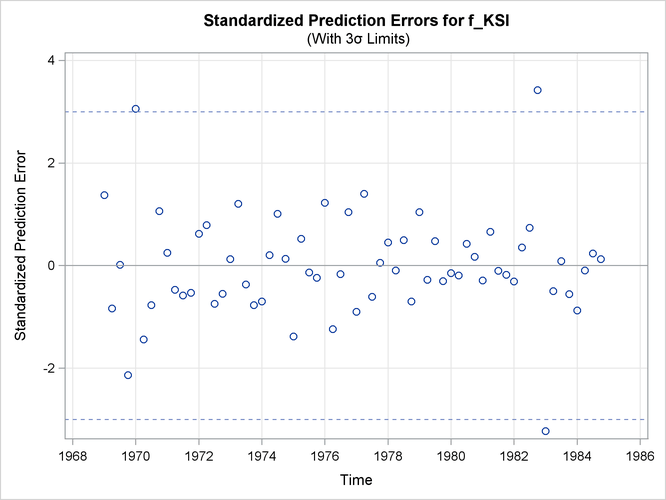

a time series plot of standardized prediction errors, one per response variable

-

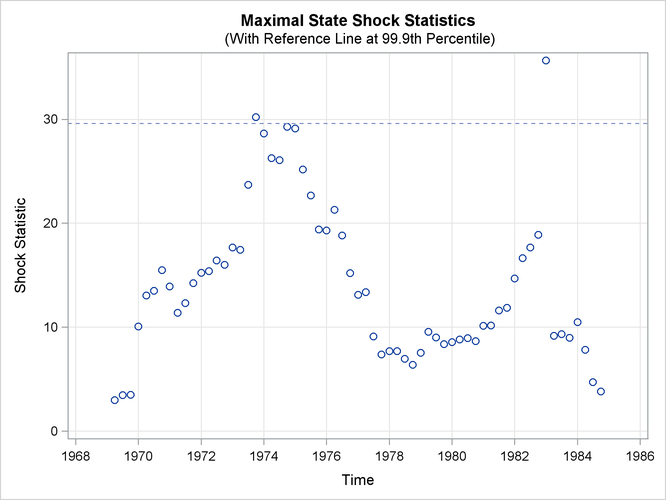

a time series plot of maximal state shock chi-square statistics

All these plots are used primarily for model diagnostics. In this example, the automobile seat-belt data that are discussed

in Example 27.1 are revisited. In Example 27.1, the question under consideration is whether the data show evidence of the effectiveness of the seat-belt law that was introduced

in the first quarter of 1983. An intervention variable, Q1_83_Shift, was used in the model to measure the effect of this law on the drivers and front-seat passengers who were killed or seriously

injured in car accidents (f_KSI). In the current example, the analysis of these data begins without the knowledge of this seat-belt law. In effect, the same

model is fitted without the use of the intervention variable Q1_83_Shift.

The following statements specify the model (without the intervention variable):

proc ssm data=seatBelt optimizer(tech=interiorpoint) plots=all;

id date interval=quarter;

state error(2) type=WN cov(g);

component wn1 = error[1];

component wn2 = error[2];

state level(2) type=RW cov(rank=1) checkbreak;

component rw1 = level[1];

component rw2 = level[2];

state season(2) type=season(length=4);

component s1 = season[1];

component s2 = season[2];

model f_KSI = rw1 s1 wn1;

model r_KSI = rw2 s2 wn2;

run;

The PLOTS=ALL option in the PROC SSM statement turns on all the plotting options. Because there are two response variables,

nine plots in total are produced: a separate set of four plots—two residual and two prediction error—is produced for f_KSI and r_KSI, and one maximal shock plot is produced. Only three of these plots are shown here. Output 27.8.1 shows the normality check for the one-step-ahead residuals for f_KSI. It shows some evidence of lack of normality.

Output 27.8.2 shows the time series plot of standardized prediction errors for f_KSI. It identifies some extreme observations (additive outliers): two near 1983 and one near 1970.

Output 27.8.3 shows the time series plot of maximal shock statistics. This plot can be very informative in showing the temporal locations

of the structural changes in the overall observation-generation process (treating the fitted model as the reference). It can

indicate locations of shifts in the process level or shifts in other characteristics, such as its slope. The precise nature

of the shift (whether the shift occurs in the level or in some other aspects) can be determined by using the CHECKBREAK option

in the appropriate STATE and TREND statements (as is done in the STATE statement in this example that defines the bivariate

state level). In this example, the maximal shock statistics plot indicates two locations—the last quarter of 1973 and the first quarter

of 1983—as likely locations for the structural breaks that are associated with the traffic accident process. These are indeed

reasonable findings, because the last quarter of 1973 (beginning in October 1973) is associated with the start of the oil

crisis that severely curtailed worldwide automobile traffic, and the first quarter of 1983 is associated with the introduction

of the seat-belt law that might have improved the safety of drivers and front-seat passengers. In addition, Output 27.8.4 shows the summary of most likely break locations for the bivariate state level. It identifies a break in the first element of level (which corresponds to the drivers and front-seat passengers) in the first quarter of 1983.

Output 27.8.4: Elementwise Break Summary for the Bivariate State: level

| Elementwise Break Summary for level |

|||

|---|---|---|---|

| ID | Element Index | Z Value | Pr > |z| |

| 1983:1 | 1 | -5.85 | <.0001 |

The following statements fit a revised model that accounts for the break in the first element of level by introducing a dummy variable, Q1_83_Pulse, in the state equation:

ods output ElementStateBreakDetails=stateBreak;

proc ssm data=seatBelt optimizer(tech=interiorpoint) plots=all;

id date interval=quarter;

Q1_83_Pulse = (date = '1jan1983'd);

zero = 0;

state error(2) type=WN cov(g);

component wn1 = error[1];

component wn2 = error[2];

state level(2) type=RW cov(rank=1) W(g)=(Q1_83_Pulse zero)

checkbreak print=breakdetail;

component rw1 = level[1];

component rw2 = level[2];

state season(2) type=season(length=4);

component s1 = season[1];

component s2 = season[2];

model f_KSI = rw1 s1 wn1;

model r_KSI = rw2 s2 wn2;

run;

Note that using Q1_83_Pulse in the definition of level is equivalent to using Q1_83_Shift in the MODEL statement for f_KSI in Example 27.1. Output 27.8.5 shows the estimated change in the first element of the state level, which is the same as the estimated level shift shown in Output 27.1.6 (this is not surprising, because these two models are statistically equivalent).

Output 27.8.5: Estimate of the Regression Coefficient of Q1_83_Pulse

| Estimate of the State Equation Regression Vector | |||||

|---|---|---|---|---|---|

| State | Element Index | Estimate | Standard Error | t Value | Pr > |t| |

| level | 1 | -0.408 | 0.0259 | -15.74 | <.0001 |

In the preceding SSM procedure statements, the CHECKBREAK option is used along with the PRINT=BREAKDETAIL option, which produces

a table that contains the break statistics at every distinct time point (this table, in turn, is captured in the output data

set stateBreak for later use). Output 27.8.6 shows the time series plot of maximal shock statistics for this revised model. As expected, the plot no longer shows the

first quarter of 1983 as a structural break location. It continues to show the last quarter of 1973 as a structural break

location, because the fitted model does not try to explicitly account for this shift.

Note that the reference line in Output 27.8.3 is drawn at the 99.9th percentile, whereas the reference line in Output 27.8.6 is drawn at the 99th percentile. The reference line location in the maximal state shock chi-square statistics plot is based

on the points in the plot. A reference line is drawn at percentile 80, 90, 99, or 99.9 based on the largest maximal shock

statistic that is shown.

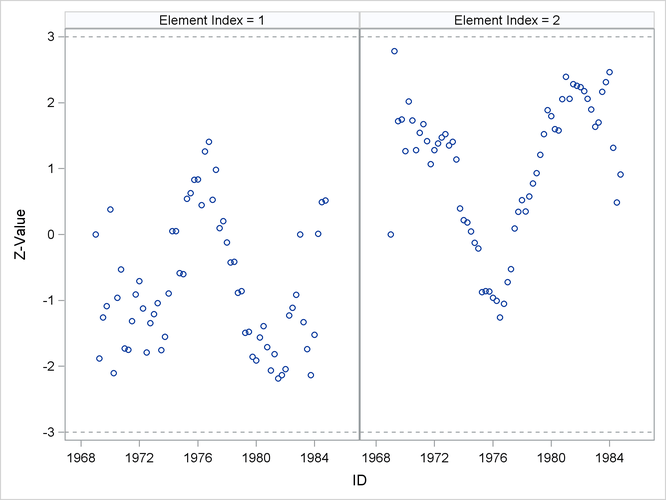

The detailed information in the data set stateBreak can be used to further investigate the possibility of significant breaks in the trend in and around 1973. The following statements

produce scatter plots for the break statistics for both the drivers and front passengers and the rear passengers (reference

lines are also drawn at –3 and 3 to check for extreme Z values):

proc sgpanel data=stateBreak;

panelby elementIndex;

scatter x=time y=zValue;

refline 3 / axis=y lineattrs=(pattern=shortdash) noclip;

refline -3 / axis=y lineattrs=(pattern=shortdash) noclip;

run;

The resulting graph, shown in Output 27.8.7, shows possible breaks in the second element—rear side passengers—around 1969. In general, however, the evidence of breaks

in the elements of level is not very strong. This means that you must look elsewhere to explain the extreme point in Output 27.8.6.