| The ARIMA Procedure |

| The MINIC Method |

The minimum information criterion (MINIC) method can tentatively identify the order of a stationary and invertible ARMA process. Note that Hannan and Rissannen (1982) proposed this method, and Box, Jenkins, and Reinsel (1994) and Choi (1992) provide useful descriptions of the algorithm.

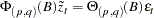

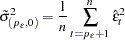

Given a stationary and invertible time series  with mean corrected form

with mean corrected form  with a true autoregressive order of

with a true autoregressive order of  and with a true moving-average order of

and with a true moving-average order of  , you can use the MINIC method to compute information criteria (or penalty functions) for various autoregressive and moving average orders. The following paragraphs provide a brief description of the algorithm.

, you can use the MINIC method to compute information criteria (or penalty functions) for various autoregressive and moving average orders. The following paragraphs provide a brief description of the algorithm.

If the series is a stationary and invertible ARMA(p, q ) process of the form

|

the error series can be approximated by a high-order AR process

|

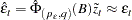

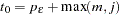

where the parameter estimates  are obtained from the Yule-Walker estimates. The choice of the autoregressive order

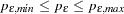

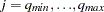

are obtained from the Yule-Walker estimates. The choice of the autoregressive order  is determined by the order that minimizes the Akaike information criterion (AIC) in the range

is determined by the order that minimizes the Akaike information criterion (AIC) in the range

|

where

|

Note that Hannan and Rissannen (1982) use the Bayesian information criterion (BIC) to determine the autoregressive order used to estimate the error series. Box, Jenkins, and Reinsel (1994) and Choi (1992) recommend the AIC.

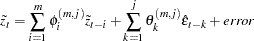

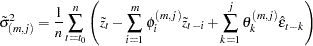

Once the error series has been estimated for autoregressive test order  and for moving-average test order

and for moving-average test order  , the OLS estimates

, the OLS estimates  and

and  are computed from the regression model

are computed from the regression model

|

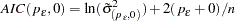

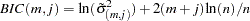

From the preceding parameter estimates, the BIC is then computed

|

where

|

where  .

.

A MINIC table is then constructed using  ; see Table 7.6. If

; see Table 7.6. If  , the preceding regression might fail due to linear dependence on the estimated error series and the mean-corrected series. Values of

, the preceding regression might fail due to linear dependence on the estimated error series and the mean-corrected series. Values of  that cannot be computed are set to missing. For large autoregressive and moving-average test orders with relatively few observations, a nearly perfect fit can result. This condition can be identified by a large negative

that cannot be computed are set to missing. For large autoregressive and moving-average test orders with relatively few observations, a nearly perfect fit can result. This condition can be identified by a large negative  value.

value.

MA |

||||||

AR |

0 |

1 |

2 |

3 |

|

|

0 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2008 by SAS Institute Inc., Cary, NC, USA. All rights reserved.