Example: Determine the Deviation of Label Positions

A manufacturing engineer

carries out a study to determine the source of excessive variation

in the positioning of labels on shampoo bottles (Hansen 1990). A labeling

machine removes bottles from the line, attaches the labels, and returns

the bottles to the line. There are six positions on the machine, and

the engineer suspects that one or more of the position heads might

be faulty.

A sample of 60 bottles,

10 per position, is run through the machine. For each bottle, the

deviation of the label is measured in millimeters, and the machine

position is recorded. In this example, you create a SAS data set named

LabelDeviations, which contains the deviation measurements for the

60 bottles.

-

Copy and paste this code into the Program tab.

data labeldeviations; input position @; do i=1 to 5; input deviation @; output; end; drop i; datalines; 1 -0.02386 -0.02853 -0.03001 -0.00428 -0.03623 1 -0.04222 -0.00144 -0.06466 0.00944 -0.00163 2 -0.02014 -0.02725 0.02268 -0.03323 0.03661 2 0.04378 0.05562 0.00977 0.05641 0.01816 3 -0.00728 0.02849 -0.04404 -0.02214 -0.01394 3 0.04855 0.03566 0.02345 0.01339 -0.00203 4 0.06694 0.10729 0.05974 0.06089 0.07551 4 0.03620 0.05614 0.08985 0.04175 0.05298 5 0.03677 0.00361 0.03736 0.01164 -0.00741 5 0.02495 -0.00803 0.03021 -0.00149 -0.04640 6 0.00493 -0.03839 -0.02037 -0.00487 -0.01202 6 0.00710 -0.03075 0.00167 -0.02845 -0.00697 run;Click to create the Work.LabelDeviations data set.

to create the Work.LabelDeviations data set.

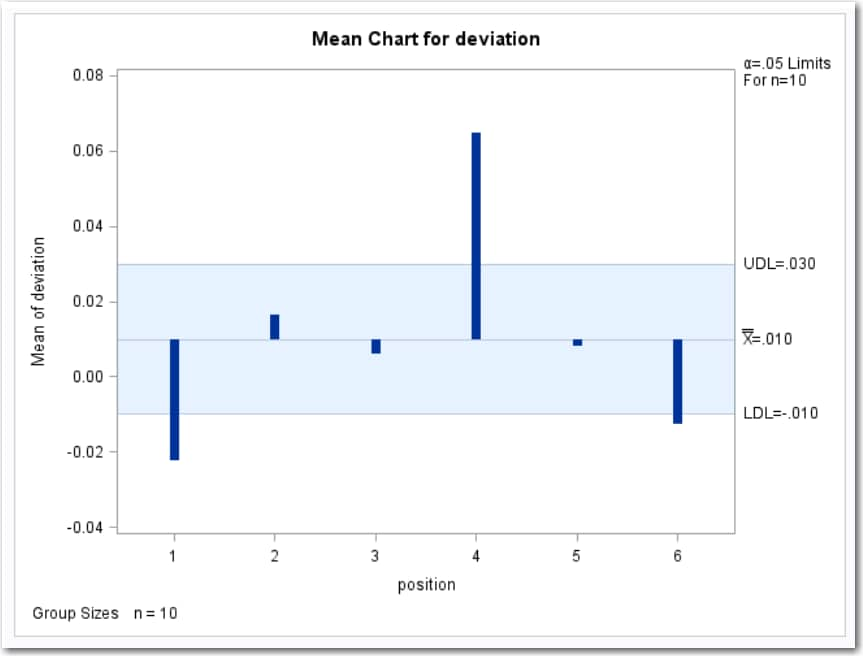

Each point on the chart

represents the average (mean) of the response measurements for a particular

sample. The average for Position 1 is below the lower decision limit

(LDL), and the average for Position 6 is slightly below the lower

decision limit. The average for Position 4 exceeds the upper decision

limit (UDL). The conclusion is that Positions 1, 4, and 6 are operating

differently.

Copyright © SAS Institute Inc. All rights reserved.