About the Control Charts Task

The Control Charts task creates Shewhart control charts

for deciding whether a process is in a state of statistical control.

Using the Control Charts task, you can create these types of charts.

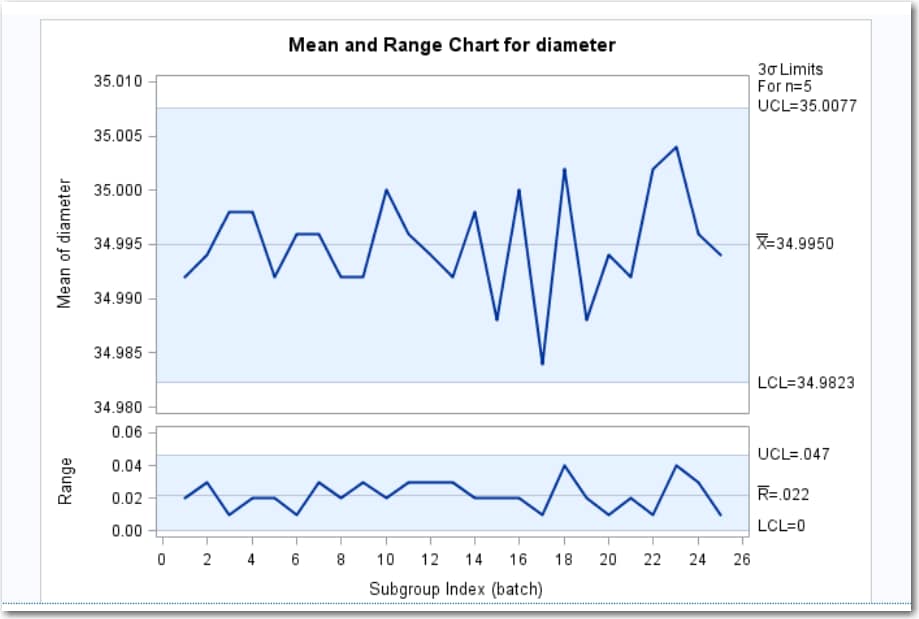

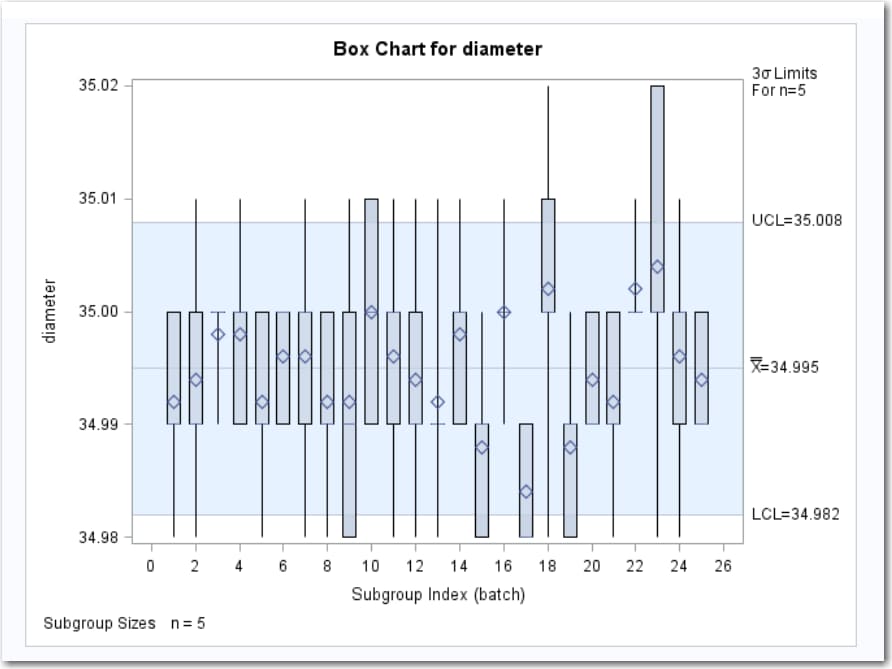

Mean and Range Chart

The Mean and Range chart

displays the subgroup means and the subgroup ranges. These charts

are useful for analyzing the central tendency and the variability

of a process.

Suppose that in the

manufacture of silicon wafers, batches of five wafers are sampled,

and their diameters are measured in millimeters. The measurements

for 25 batches are stored in a SAS data set, which is used to create

the mean and range charts. Each point on the mean chart represents

the average (mean) of the measurements for a particular batch. Each

point on the range chart represents the range of the measurements

for a particular batch. If all the points fall within the control

limits, you can conclude that the process is in statistical control.

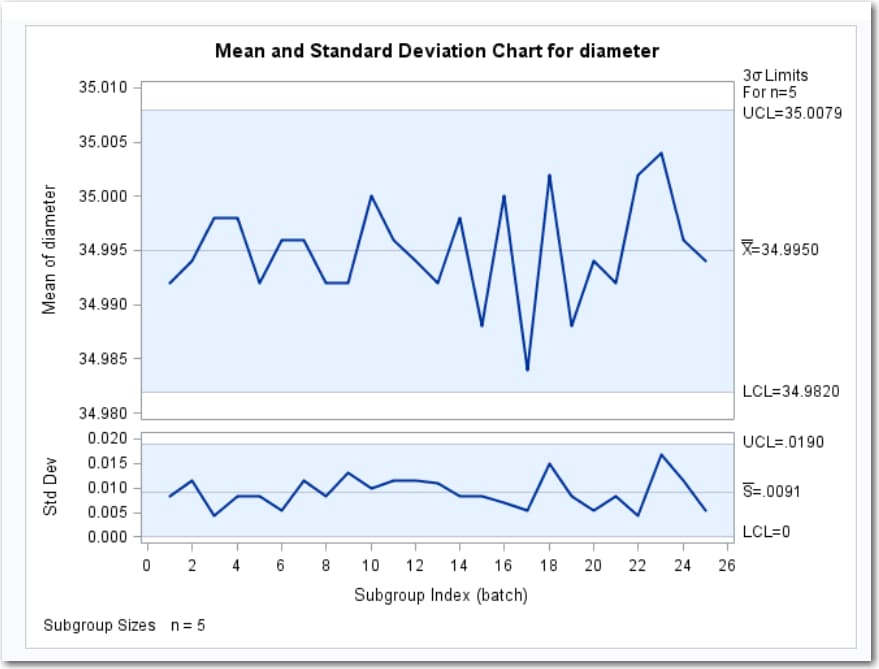

Mean and Standard Deviation Chart

The Mean and Standard

Deviation chart displays the subgroup means and the subgroup standard

deviations. These charts are useful for analyzing the central tendency

and the variability of a process.

You might want to use

this chart to find the distribution of the output and to determine

whether a process is in statistical control. For example, suppose

a petroleum company uses a turbine to heat water into steam that is

pumped into the ground to make oil less viscous and easier to extract.

This process occurs 20 times daily, and the amount of power (in kilowatts)

that is used to heat the water to the desired temperature is recorded.

Each point on the mean chart represents the mean of the measurements

for a particular day. Each point on the standard deviation chart represents

the standard deviation of the measurements for a particular day. If

all the points lie within the control limits, it can be concluded

that the process is in statistical control.

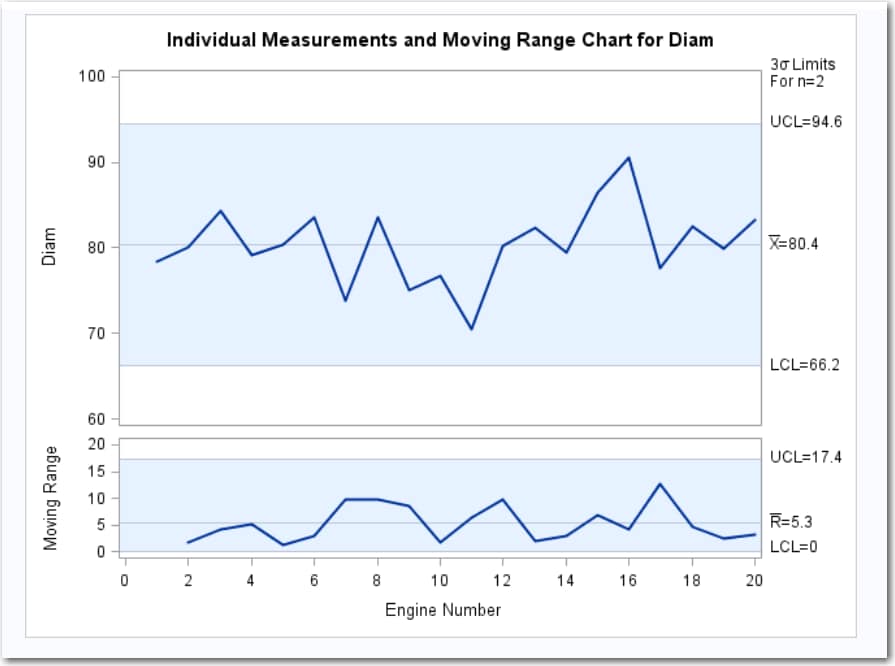

Individual Measurements

The Individual Measurements

chart displays the individual measurements and the moving ranges.

These charts are appropriate when only one measurement is available

for each subgroup sample and when the measurements are independently

and normally distributed. You might want to use this task to analyze

a manufacturing process.

Suppose that an aeronautics

company that manufactures jet engines measures the inner diameter

of the forward face of each engine (in centimeters). The diameter

measurements of 20 engines are stored in a SAS data set. Each point

on the individual measurements chart indicates the inner diameter

of a particular engine. Each point on the moving range chart indicates

the range of the two most recent measurements. If all the individual

measurements and moving ranges fall within the control limits, you

can conclude that the process is in statistical control.

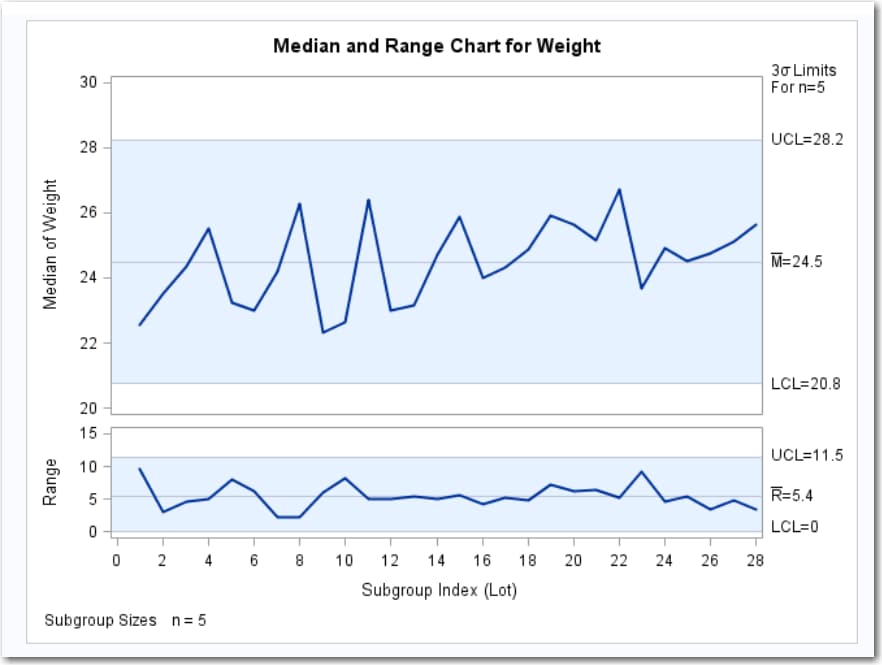

Median and Range Chart

The Median and Range

chart displays the subgroup medians and ranges, which are used to

analyze the central tendency and variability of a process.

A consumer products

company weighs detergent boxes (in pounds) to determine whether the

fill process is in control. The Detergent data set contains the weights

for five boxes in each of 28 lots. A lot is considered a rational

subgroup.

Each point on the median

chart represents the median of the measurements for a particular lot.

For example, the weights for the first lot are 17.39, 19.34, 22.56,

24.49, and 26.93, and consequently, the median plotted for this lot

is 22.56. Each point on the range chart represents the range of the

measurements for a particular batch. For example, the range plotted

for the first lot is 26.93–17.39=9.54. Because all of the points

lie within the control limits, you can conclude that the process is

in statistical control.

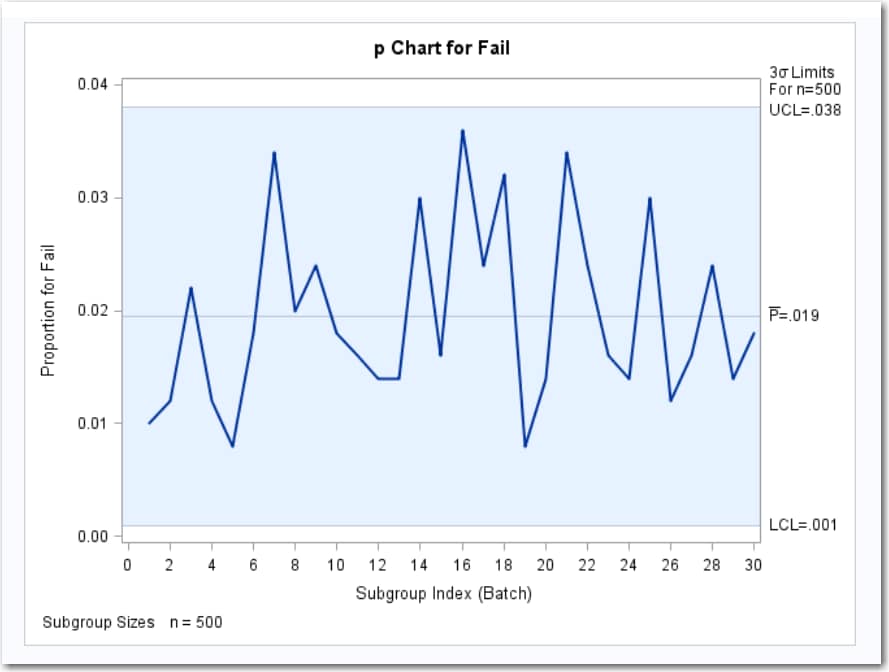

p Charts

p charts display proportions

of nonconforming (defective) items in the subgroup samples. You might

want to use this task to monitor the proportion of defects in a manufacturing

process.

Suppose that an electronics

company manufactures circuits in batches of 500 and uses a p chart

to monitor the proportion of failing circuits. Thirty batches are

examined, and the failures in each batch are counted. The failure

counts are stored in a SAS data set, which is used to create the p

chart. Each point on the p chart represents the proportion of nonconforming

items in a particular subgroup. For example, if the number of failures

in the first circuit is 5, then the value that is plotted for the

first batch is 5/500=0.01. If all the points fall within the control

limits, it can be concluded that the process is in statistical control.

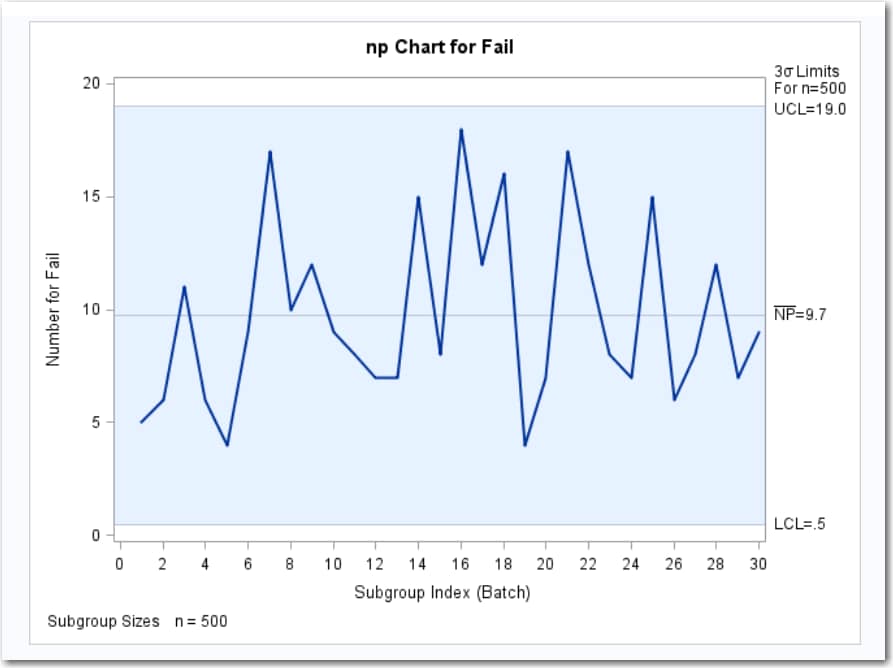

np Charts

np charts display the

numbers of nonconformities (defects) in the subgroup samples. You

might want to use this task to monitor the number of defects in a

manufacturing process.

Suppose that an electronics

company manufactures circuits in batches of 500 and uses an np chart

to monitor the number of failing circuits. Thirty batches are examined,

and the failures in each batch are counted. The failure counts are

stored in a SAS data set, which is used to create the np chart. Each

point on the np chart represents the number of nonconforming items

in a particular subgroup. For example, the value that is plotted for

the first batch is 5. If all the points fall within the control limits,

it can be concluded that the process is in statistical control.

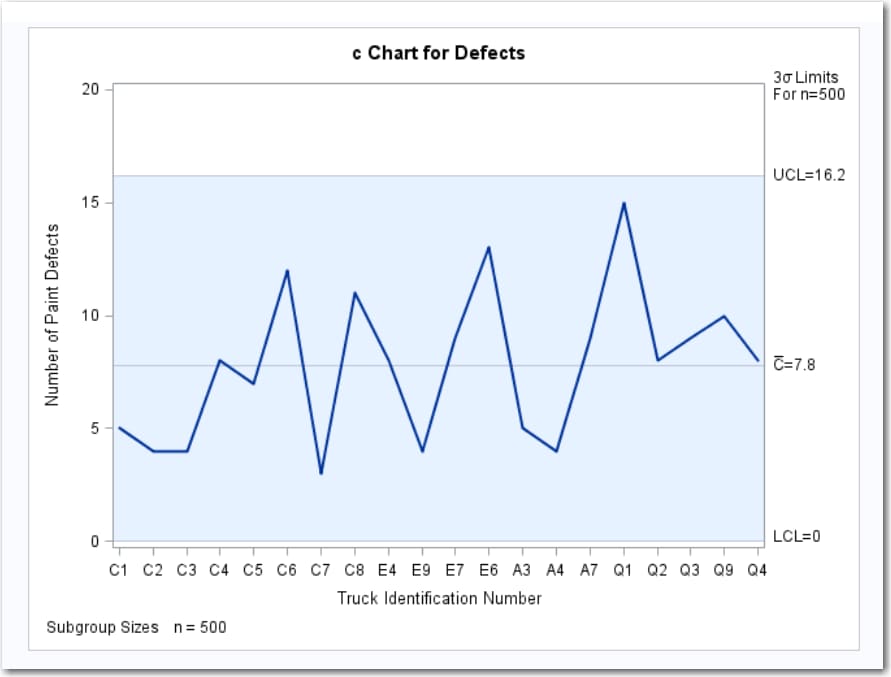

c Chart

c charts display the

numbers of nonconformities (defects) in the subgroup samples. You

might want to use a c chart to monitor the number of defects that

are found in a new product.

Suppose that an automobile

company wants to monitor the number of paint defects on its new trucks.

Twenty trucks of the same model are inspected, and the number of paint

defects per truck is recorded. Each point on the c chart represents

the number of defects for a given truck. If all the points fall within

the control limits, it can be concluded that the process is in statistical

control.

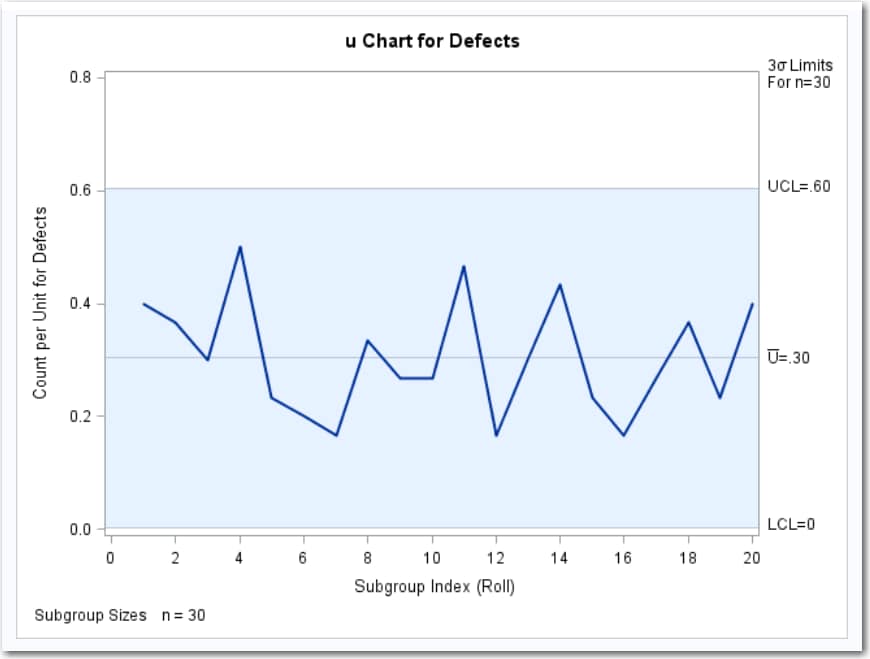

u Chart

u charts display the

numbers of nonconformities (defects) per inspection unit in the subgroup

samples that contain arbitrary numbers of units. You might want to

use this task to determine the number of defects per inspection unit

that resulted from a manufacturing process.

Suppose that a textile

company uses a u chart to monitor the number of defects per square

meter of fabric. The fabric is spooled onto rolls as it is inspected

for defects. Each piece of fabric is one meter wide and 30 meters

long. The defect counts for 20 rolls are saved in a SAS data set,

which is used to create the u chart. Each point on the u chart represents

the number of nonconformities per inspection unit for a particular

subgroup. For example, the value that is plotted for the first subgroup

is 12/30=0.4 (because there are 12 defects on the first roll and the

roll contains 30 square meters of fabric). If none of the points exceed

the control limit (which is 3 sigma by default), the u chart indicates

that the fabric manufacturing process is in statistical control.

Copyright © SAS Institute Inc. All rights reserved.