The MVPMONITOR Procedure

The following statements use PROC MVPMODEL to create a model from which classical ![]() charts can be produced:

charts can be produced:

proc mvpmodel data=flightDelays ncomp=all noprint out=mvpout; var AA CO DL F9 FL NW UA US WN; run;

The NCOMP=

ALL option specifies that the number of principal components equal the number of process variables, so the mvpout data set contains the classical ![]() statistic for each observation. The

statistic for each observation. The mvpout data set contains six observations per time point—one for each region.

The following statements create the classical ![]() chart:

chart:

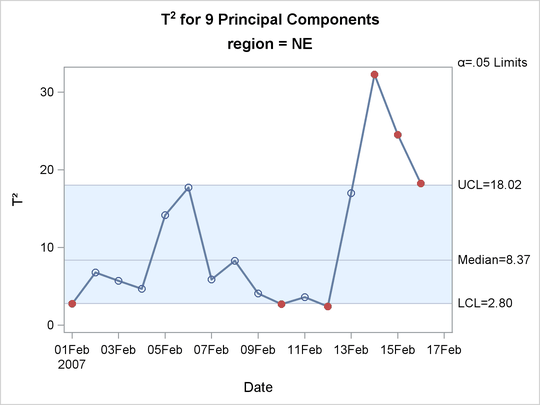

proc mvpmonitor history=mvpout; time flightDate; series region; tsquarechart / seriesvalue='NE'; run;

The SERIES

statement specifies region as the variable that identifies sequences of ![]() statistics, and the SERIESVALUE=

option selects the region to be plotted, the Northeast. The classical

statistics, and the SERIESVALUE=

option selects the region to be plotted, the Northeast. The classical ![]() chart is shown in Output 13.4.1.

chart is shown in Output 13.4.1.

In this case, the classical ![]() chart finds out-of-control observations above the upper control limit during February 14–16 and below the lower control limit

on February 1, 10, and 12.

chart finds out-of-control observations above the upper control limit during February 14–16 and below the lower control limit

on February 1, 10, and 12.

Output 13.4.2 shows a partial listing of the mvpout data set. It contains ![]() statistics based on the model that has nine principal components, in addition to the original variables and other observationwise

statistics.

statistics based on the model that has nine principal components, in addition to the original variables and other observationwise

statistics.

Output 13.4.2: Partial Listing of Output Data Set mvpout

| flightDate | region | AA | CO | DL | F9 | FL | NW | UA | US | WN | Prin1 | Prin2 | Prin3 | Prin4 | Prin5 | Prin6 | Prin7 | Prin8 | Prin9 | _NOBS_ | _TSQUARE_ | R_AA | R_CO | R_DL | R_F9 | R_FL | R_NW | R_UA | R_US | R_WN | _SPE_ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 02/01/07 | MW | 14.9 | 7.1 | 7.9 | 8.5 | 14.8 | 4.5 | 5.1 | 13.4 | 5.1 | -1.16440 | 0.89425 | 0.00118 | -0.84496 | 0.07443 | -0.05231 | -0.27403 | 0.31880 | -0.06726 | 96 | 3.2122 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | . |

| 02/01/07 | NE | 15.7 | 7.1 | 8.6 | 6.3 | 14.6 | 6.2 | 7.0 | 11.0 | 6.4 | -1.08197 | 0.55936 | 0.05859 | -0.84487 | -0.02092 | -0.16851 | -0.30596 | 0.25090 | 0.12804 | 96 | 2.7349 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | . |

| 02/01/07 | NW | 17.8 | 2.6 | 6.1 | 28.8 | 11.6 | 6.1 | 11.6 | 27.3 | 3.7 | -0.31223 | 2.23593 | -0.03824 | 0.58893 | 0.21628 | 0.67149 | 0.85708 | 1.07348 | -0.49530 | 96 | 18.5555 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | . |

| 02/01/07 | SC | 19.9 | 8.3 | 13.9 | 4.9 | 25.8 | 15.3 | 9.0 | 15.1 | 12.8 | 0.22974 | -0.16976 | 0.56118 | -1.30139 | 0.22990 | -0.34406 | 0.11471 | 0.30201 | 0.46481 | 96 | 6.3335 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | . |

| 02/01/07 | SE | 16.1 | 1.9 | 8.7 | 8.7 | 15.1 | 18.3 | 4.0 | 10.4 | 6.5 | -0.87056 | 0.01044 | 1.06975 | -0.50179 | 0.38041 | -0.33789 | 0.63114 | 0.45028 | 0.21437 | 96 | 6.1537 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | . |

Notice that no SPE statistics are produced when the number of principal components equals the number of process variables.