CCHART Statement: SHEWHART Procedure

Constructing Charts for Numbers of Nonconformities (c Charts)

The following notation is used in this section:

|

u |

expected number of nonconformities per unit produced by the process |

|

|

|

number of nonconformities per unit in the ith subgroup |

|

|

|

total number of nonconformities in the ith subgroup |

|

|

|

number of inspection units in the ith subgroup. Typically, |

|

|

|

average number of nonconformities per unit taken across subgroups. The quantity

|

|

|

N |

number of subgroups |

|

|

|

has a central |

Plotted Points

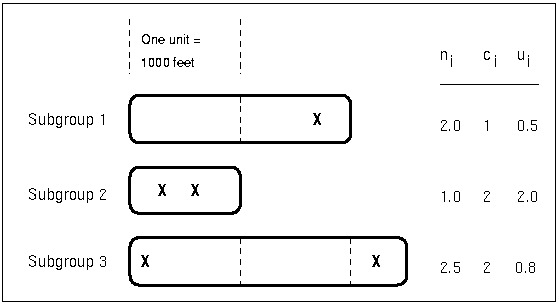

Each point on a c chart represents the total number of nonconformities (![]() ) in a subgroup. For example, Figure 17.24 displays three sections of pipeline that are inspected for defective welds (indicated by an X). Each section represents a subgroup composed of a number of inspection units, which are 1000-foot-long sections. The number of units in the ith subgroup is denoted by

) in a subgroup. For example, Figure 17.24 displays three sections of pipeline that are inspected for defective welds (indicated by an X). Each section represents a subgroup composed of a number of inspection units, which are 1000-foot-long sections. The number of units in the ith subgroup is denoted by ![]() , which is the subgroup sample size. The value of

, which is the subgroup sample size. The value of ![]() can be fractional; Figure 17.24 shows

can be fractional; Figure 17.24 shows ![]() units in the third subgroup.

units in the third subgroup.

Figure 17.24: Terminology for c Charts and u Charts

The number of nonconformities in the ith subgroup is denoted by ![]() . The number of nonconformities per unit in the ith subgroup is denoted by

. The number of nonconformities per unit in the ith subgroup is denoted by ![]() . In Figure 17.24, the number of welds per inspection unit in the third subgroup is

. In Figure 17.24, the number of welds per inspection unit in the third subgroup is ![]() .

.

A u chart created with the UCHART statement plots the quantity ![]() for the ith subgroup (see UCHART Statement: SHEWHART Procedure). An advantage of a u chart is that the value of the central line at the ith subgroup does not depend on

for the ith subgroup (see UCHART Statement: SHEWHART Procedure). An advantage of a u chart is that the value of the central line at the ith subgroup does not depend on ![]() . This is not the case for a c chart, and consequently, a u chart is often preferred when the number of units

. This is not the case for a c chart, and consequently, a u chart is often preferred when the number of units ![]() is not constant across subgroups.

is not constant across subgroups.

Central Line

On a c chart, the central line indicates an estimate for ![]() , which is computed as

, which is computed as ![]() . If you specify a known value (

. If you specify a known value (![]() ) for u, the central line indicates the value of

) for u, the central line indicates the value of ![]() .

.

Note that the central line varies with subgroup sample size ![]() . When

. When ![]() for all subgroups, the central line has the constant value

for all subgroups, the central line has the constant value ![]() .

.

Control Limits

You can compute the limits in the following ways:

-

as a specified multiple (k) of the standard error of

above and below the central line. The default limits are computed with k = 3 (these are referred to as

above and below the central line. The default limits are computed with k = 3 (these are referred to as  limits).

limits).

-

as probability limits defined in terms of

, a specified probability that

, a specified probability that  exceeds the limits

exceeds the limits

The lower and upper control limits, LCLC and UCLC respectively, are given by

|

|

|

|

|

|

|

|

The upper and lower control limits vary with the number of inspection units per subgroup ![]() . If

. If ![]() for all subgroups, the control limits have constant values.

for all subgroups, the control limits have constant values.

|

|

|

|

|

|

|

|

An upper probability limit UCLC for ![]() can be determined using the fact that

can be determined using the fact that

|

|

The upper probability limit UCLC is then calculated by setting

|

|

and solving for UCLC.

A similar approach is used to calculate the lower probability limit LCLC, using the fact that

|

|

The lower probability limit LCLC is then calculated by setting

|

|

and solving for LCLC. This assumes that the process is in statistical control and that ![]() has a Poisson distribution. For more information, refer to Johnson, Kotz, and Kemp (1992). Note that the probability limits vary with the number of inspection units per subgroup (

has a Poisson distribution. For more information, refer to Johnson, Kotz, and Kemp (1992). Note that the probability limits vary with the number of inspection units per subgroup (![]() ) and are asymmetric about the central line.

) and are asymmetric about the central line.

If a standard value ![]() is available for u, replace

is available for u, replace ![]() with

with ![]() in the formulas for the control limits. You can specify parameters for the limits as follows:

in the formulas for the control limits. You can specify parameters for the limits as follows:

-

Specify k with the SIGMAS= option or with the variable

_SIGMAS_in a LIMITS= data set. -

Specify

with the ALPHA= option or with the variable

with the ALPHA= option or with the variable _ALPHA_in a LIMITS= data set. -

Specify a constant nominal sample size

for the control limits with the LIMITN= option or with the variable

for the control limits with the LIMITN= option or with the variable _LIMITN_in a LIMITS= data set. -

Specify

with the U0= option or with the variable

with the U0= option or with the variable _U_in a LIMITS= data set.