UCHART Statement: SHEWHART Procedure

Constructing Charts for Nonconformities per Unit (u Charts)

The following notation is used in this section:

|

expected number of nonconformities per unit produced by process |

||||

|

number of nonconformities per unit in the |

||||

|

total number of nonconformities in the |

||||

|

number of inspection units in the |

||||

|

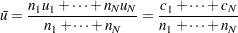

average number of nonconformities per unit taken across subgroups. The quantity

|

||||

|

number of subgroups |

||||

|

has a central |

Plotted Points

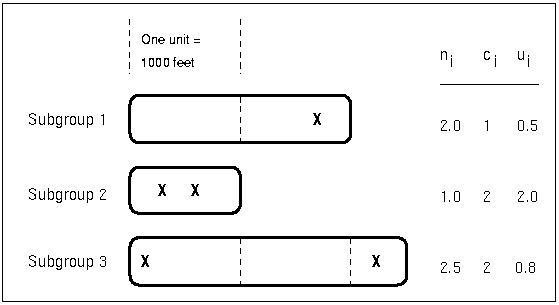

Each point on a  chart indicates the number of nonconformities per unit (

chart indicates the number of nonconformities per unit ( ) in a subgroup. For example, Figure 15.96 displays three sections of pipeline that are inspected for defective welds (indicated by an X). Each section represents a subgroup composed of a number of inspection units, which are 1000-foot-long sections. The number of units in the

) in a subgroup. For example, Figure 15.96 displays three sections of pipeline that are inspected for defective welds (indicated by an X). Each section represents a subgroup composed of a number of inspection units, which are 1000-foot-long sections. The number of units in the  th subgroup is denoted by

th subgroup is denoted by  , which is the subgroup sample size.

, which is the subgroup sample size.

Charts and

Charts and  Charts

Charts

The number of nonconformities in the  th subgroup is denoted by

th subgroup is denoted by  . The number of nonconformities per unit in the

. The number of nonconformities per unit in the  th subgroup is denoted by

th subgroup is denoted by  . In Figure 15.96, the number of defective welds per unit in the third subgroup is

. In Figure 15.96, the number of defective welds per unit in the third subgroup is  .

.

A  chart plots the quantity

chart plots the quantity  for the

for the  th subgroup. A

th subgroup. A  chart plots the quantity

chart plots the quantity  for the

for the  th subgroup (see CCHART Statement: SHEWHART Procedure). An advantage of a

th subgroup (see CCHART Statement: SHEWHART Procedure). An advantage of a  chart is that the value of the central line at the

chart is that the value of the central line at the  th subgroup does not depend on

th subgroup does not depend on  . This is not the case for a

. This is not the case for a  chart, and consequently, a

chart, and consequently, a  chart is often preferred when the number of units

chart is often preferred when the number of units  is not constant across subgroups.

is not constant across subgroups.

Central Line

On a  chart, the central line indicates an estimate of

chart, the central line indicates an estimate of  , which is computed as

, which is computed as  by default. If you specify a known value (

by default. If you specify a known value ( ) for

) for  , the central line indicates the value of

, the central line indicates the value of  .

.

Control Limits

You can compute the limits in the following ways:

as a specified multiple (

) of the standard error of

) of the standard error of  above and below the central line. The default limits are computed with

above and below the central line. The default limits are computed with  (these are referred to as

(these are referred to as  limits).

limits). as probability limits defined in terms of

, a specified probability that

, a specified probability that  exceeds the limits

exceeds the limits

The lower and upper control limits, LCLU and UCLU, respectively, are given by

|

|

|

|||

|

|

|

The limits vary with  .

.

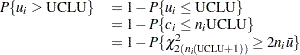

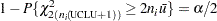

The upper probability limit UCLU for  can be determined using the fact that

can be determined using the fact that

|

The limit UCLU is then calculated by setting

|

and solving for UCLU.

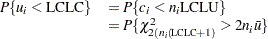

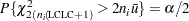

Likewise, the lower probability limit LCLC for  can be determined using the fact that

can be determined using the fact that

|

The limit LCLC is then calculated by setting

|

and solving for LCLC. For more information, refer to Johnson, Kotz, and Kemp (1992). This assumes that the process is in statistical control and that  has a Poisson distribution. Note that the probability limits vary with

has a Poisson distribution. Note that the probability limits vary with  and are asymmetric around the central line. If a standard value

and are asymmetric around the central line. If a standard value  is available for

is available for  , replace

, replace  with

with  in the formulas for the control limits.

in the formulas for the control limits.

You can specify parameters for the limits as follows:

Specify

with the SIGMAS= option or with the variable _SIGMAS_ in a LIMITS= data set.

with the SIGMAS= option or with the variable _SIGMAS_ in a LIMITS= data set. Specify

with the ALPHA= option or with the variable _ALPHA_ in a LIMITS= data set.

with the ALPHA= option or with the variable _ALPHA_ in a LIMITS= data set. Specify a constant nominal sample size

for the control limits with the LIMITN= option or with the variable _LIMITN_ in a LIMITS= data set.

for the control limits with the LIMITN= option or with the variable _LIMITN_ in a LIMITS= data set. Specify

with the U0= option or with the variable _U_ in a LIMITS= data set.

with the U0= option or with the variable _U_ in a LIMITS= data set.

.

.

distribution with

distribution with  degrees of freedom

degrees of freedom