NPCHART Statement: SHEWHART Procedure

Example 15.19 Specifying Standard Average Proportion

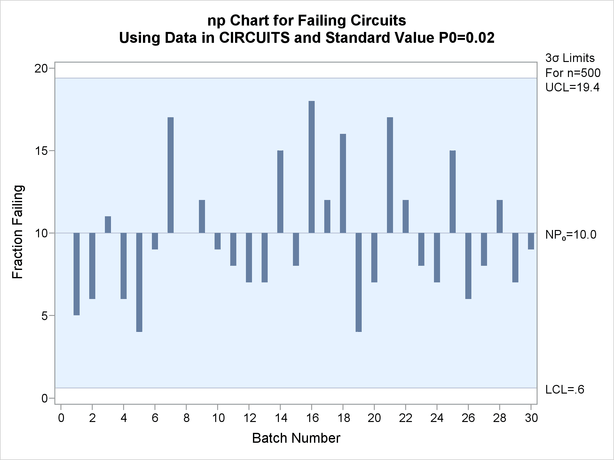

[See SHWNP3 in the SAS/QC Sample Library]In some situations, a standard (known) value ( ) is available for the expected proportion of nonconforming items, based on extensive testing or previous sampling. This example illustrates how you can specify

) is available for the expected proportion of nonconforming items, based on extensive testing or previous sampling. This example illustrates how you can specify  to create an

to create an  chart.

chart.

An  chart is used to monitor the number of failing circuits in the data set Circuits, which is introduced in Creating np Charts from Count Data. The expected proportion of failing circuits is known to be

chart is used to monitor the number of failing circuits in the data set Circuits, which is introduced in Creating np Charts from Count Data. The expected proportion of failing circuits is known to be  . The following statements create an

. The following statements create an  chart, shown in Output 15.19.1, using

chart, shown in Output 15.19.1, using  to compute the control limits:

to compute the control limits:

title1 'np Chart for Failing Circuits';

title2 'Using Data in CIRCUITS and Standard Value P0=0.02';

proc shewhart data=Circuits;

npchart Fail*Batch / subgroupn = 500

p0 = 0.02

npsymbol = np0

nolegend

needles

odstitle = title

odstitle2 = title2;

label Batch ='Batch Number'

Fail ='Fraction Failing';

run;

Chart with Standard Value of

Chart with Standard Value of

The chart indicates that the process is in control. The P0= option specifies  . The NPSYMBOL= option specifies a label for the central line indicating that the line represents a standard value. The NEEDLES option connects points to the central line with vertical needles. The NOLEGEND option suppresses the default legend for subgroup sample sizes. Labels for the vertical and horizontal axes are provided with the LABEL statement. For details concerning axis labeling, see Axis Labels.

. The NPSYMBOL= option specifies a label for the central line indicating that the line represents a standard value. The NEEDLES option connects points to the central line with vertical needles. The NOLEGEND option suppresses the default legend for subgroup sample sizes. Labels for the vertical and horizontal axes are provided with the LABEL statement. For details concerning axis labeling, see Axis Labels.

Alternatively, you can specify  using the variable _P_ in a LIMITS= data set, as follows:

using the variable _P_ in a LIMITS= data set, as follows:

data Climits;

length _var_ _subgrp_ _type_ $8;

_p_ = 0.02;

_subgrp_ = 'Batch';

_var_ = 'Fail';

_type_ = 'STANDARD';

_limitn_ = 500;

proc shewhart data=Circuits limits=Climits;

npchart Fail*Batch / subgroupn = 500

npsymbol = np0

nolegend

needles;

label Batch ='Batch Number'

Fail ='Fraction Failing';

run;

The bookkeeping variable _TYPE_ indicates that _P_ has a standard value. The chart produced by these statements is identical to the chart in Output 15.19.1.