Details: MVPMONITOR Procedure

Computation of  Control Limits

Control Limits

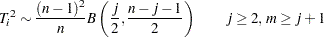

The control limits for the  chart are the same for all of the

chart are the same for all of the  statistics on the chart. The control limits are computed using the method of Tracy, Young, and Mason (1992), in which the distribution of the

statistics on the chart. The control limits are computed using the method of Tracy, Young, and Mason (1992), in which the distribution of the  statistic is shown to follow a scaled beta distribution:

statistic is shown to follow a scaled beta distribution:

|

Here,  denotes the observation,

denotes the observation,  denotes the number of principal components in the model, and

denotes the number of principal components in the model, and  denotes the number of observations.

denotes the number of observations.

The upper control limit is computed as the  quantile of this distribution, and the lower control limit is computed by the

quantile of this distribution, and the lower control limit is computed by the  quantile. You can use the ALPHA= option in the TSQUARECHART statement to specify the

quantile. You can use the ALPHA= option in the TSQUARECHART statement to specify the  .

.

Computation of SPE Control Limits

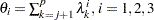

The SPE chart plots the sum of squares of the residuals from the principal components model. If either  or the data matrix has rank less than

or the data matrix has rank less than  , then the SPE statistic is not defined and an SPE chart is not produced. The SPE statistic for observation

, then the SPE statistic is not defined and an SPE chart is not produced. The SPE statistic for observation  is denoted

is denoted

|

where  is the number of variables and

is the number of variables and  is the

is the  th observation for the

th observation for the  th variable in the error matrix,

th variable in the error matrix,  , in the principal components model

, in the principal components model

|

The distribution of  has been approximated in the literature under different conditions. Two methods for computing control limits for

has been approximated in the literature under different conditions. Two methods for computing control limits for  are implemented by the MVPMONITOR procedure. One method is used when the data used to build the principal components model consists of a single measurement per time point. The other method applies when there are multiple measurements per time point (Jensen and Solomon; 1972; Nomikos and MacGregor; 1995).

are implemented by the MVPMONITOR procedure. One method is used when the data used to build the principal components model consists of a single measurement per time point. The other method applies when there are multiple measurements per time point (Jensen and Solomon; 1972; Nomikos and MacGregor; 1995).

One Observation per Time Point

When there is a single observation at each time point, the data matrix  is

is  , with exactly one observation at each time point in either the DATA= or HISTORY= data set. The derivation of the control limits uses the central limit theorem approach of Jensen and Solomon (1972). They begin by defining

, with exactly one observation at each time point in either the DATA= or HISTORY= data set. The derivation of the control limits uses the central limit theorem approach of Jensen and Solomon (1972). They begin by defining  , where

, where  is the

is the  th eigenvalue from the principal components model.

th eigenvalue from the principal components model.

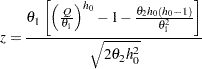

Then the quantity

|

is distributed  as

as  , where

, where  is defined as

is defined as  . The upper control limit for all

. The upper control limit for all  is then computed by

is then computed by

|

where  is the

is the  percentile of the standard normal distribution. The lower control limit is obtained similarly using

percentile of the standard normal distribution. The lower control limit is obtained similarly using  . You can specify

. You can specify  with the ALPHA= option in the SPECHART statement.

with the ALPHA= option in the SPECHART statement.

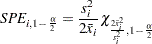

Multiple Observations per Time Point

When there are multiple observations at each time period in the DATA= data set to PROC MVPMODEL, a different approximation of the SPE distribution is used to compute control limits. The approximate distribution at time  is the scaled chi-squared distribution:

is the scaled chi-squared distribution:

|

where  and

and  are the mean and variance of the SPE statistics at time

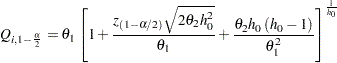

are the mean and variance of the SPE statistics at time  . The upper control limit for all observations at time point

. The upper control limit for all observations at time point  is computed as the

is computed as the  percentile of the scaled chi-squared distribution:

percentile of the scaled chi-squared distribution:

|

Similarly the lower control limit is computed from the  percentile. You can specify

percentile. You can specify  with the ALPHA= option in the SPECHART statement.

with the ALPHA= option in the SPECHART statement.

In this experimental version of PROC MVPMONITOR, it is not possible to create an SPE chart for multiple observations per time point in a Phase II analysis. For additional details concerning the distribution approximations, refer to Nomikos and MacGregor (1995) and Jackson and Mudholkar (1979).

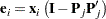

Contribution Plots

One way to diagnose the behavior of out-of-control points in multivariate charts is with contribution plots (Miller, Swanson, and Heckler; 1998). These plots tell you which variables contribute to the distance between the points in a score, SPE, or  chart and the sample mean of the data.

chart and the sample mean of the data.

A contribution plot is a bar chart of the contributions of the process variables to the statistic. For the  th SPE statistic, the contribution of the

th SPE statistic, the contribution of the  th variable is the

th variable is the  th entry of the vector

th entry of the vector  , which is computed as

, which is computed as

|

Here  is the vector of errors from the principal components model for observation

is the vector of errors from the principal components model for observation  and

and  is the

is the  th observation. The contributions to the

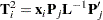

th observation. The contributions to the  th

th  statistic are computed similarly as the entries of the vector

statistic are computed similarly as the entries of the vector

|

where  is the matrix of the first

is the matrix of the first  eigenvectors and

eigenvectors and  is the diagonal matrix of the first

is the diagonal matrix of the first  eigenvalues.

eigenvalues.

Note: This procedure is experimental.