| The PARETO Procedure |

Creating a Pareto Chart from Raw Data

[See PARETO4 in the SAS/QC Sample Library]In the fabrication of integrated circuits, common causes of failures include improper doping, corrosion, surface contamination, silicon defects, metallization, and oxide defects. The causes of 31 failures were recorded in a SAS data set called Failure1.

data Failure1; length Cause $ 16 ; label Cause = 'Cause of Failure' ; input Cause & $; datalines; Corrosion Oxide Defect Contamination Oxide Defect Oxide Defect Miscellaneous Oxide Defect Contamination Metallization Oxide Defect Contamination Contamination Oxide Defect Contamination Contamination Contamination Corrosion Silicon Defect Miscellaneous Contamination Contamination Contamination Miscellaneous Contamination Contamination Doping Oxide Defect Oxide Defect Metallization Contamination Contamination ; run;

Each of the 31 observations corresponds to a different circuit, and the value of Cause provides the cause for the failure. These are raw data in the sense that there is more than one observation with the same value of Cause, and the observations are not sorted by Cause. The following statements produce a basic Pareto chart for the failures:

proc pareto data=Failure1; hbar Cause; run;

The PARETO procedure is invoked with the first statement, referred to as the PROC statement. You specify the process variable to be analyzed in the HBAR statement.

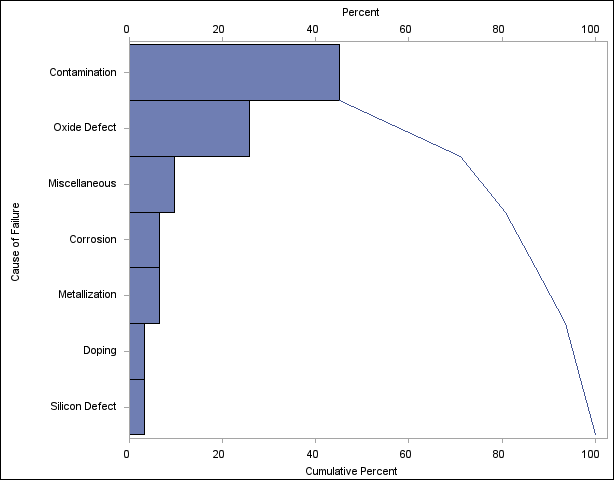

The Pareto chart is shown in Figure 11.1.

The procedure has classified the values of Cause into seven distinct categories (levels). The bars represent the percent of failures in each category, and they are arranged in decreasing order. Thus, the most frequently occurring category is Contamination, which accounts for 45% of the failures. The Pareto curve indicates the cumulative percent of failures from top to bottom; for example, Contamination and Oxide together account for 71% of the failures.

If there is sufficient space, the procedure labels the bars along the vertical axis as in Figure 11.1. Otherwise the procedure numbers the bars from top to bottom and adds a legend identifying the categories.

A category legend is likely to be introduced when

the number of categories is large

the category labels are lengthy. Category labels can be up to 64 characters.

a large text height is used. You can specify the height with the HEIGHT= option in the HBAR statement or with the HTEXT= option in a GOPTIONS statement.

Copyright © SAS Institute, Inc. All Rights Reserved.