| The GAGE Application |

| Invoking the GAGE Application |

The interface to the GAGE application was implemented using FRAME entries in SAS/AF software. The application is stored in the gage catalog. (File extensions for SAS catalogs differ based on the operating system.) gage cataloggage catalog

Assume that you are using the SAS System under Microsoft Windows and that the SAS/QC Sample Library is stored in the c:\sas\qc\sample directory. (Check with your SAS site representative for the location of the Sample Library on your system.) You invoke the application as follows:

First you must tell the SAS System where the catalog is stored:

libname gage 'c:\sas\qc\sample';

You then issue the following command from any SAS display manager window:

af c=gage.gage.gage.frame

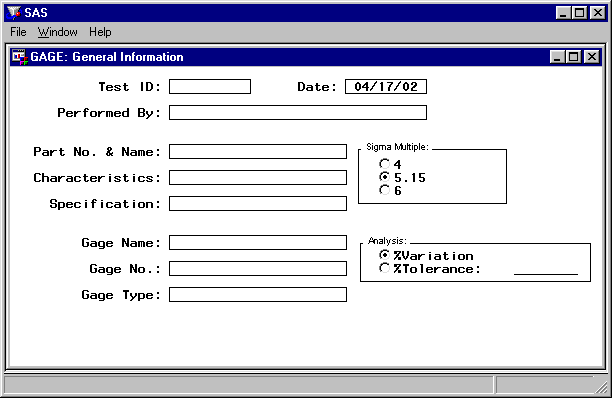

The main window in the application appears, as shown in Figure A.1.

You specify the following general information for your gage study in this window: who performed the study, part number and part name, characteristics, specification, and gage name, number, and type.

The test ID is required for each set of data to be analyzed. It uniquely identifies each gage study. Date is set to the current date and can be changed. You also select either the percent of process variation analysis (%Variation) or the percent of tolerance analysis (%Tolerance). You must specify a tolerance value for the percent of tolerance analysis.

Set the multiple of sigma to whatever level you use for gage studies. This multiple may be a standard level established within your organization. For example, the automotive industry typically uses  (ASQC Automotive Division/AIAG 1990), and SEMATECH uses

(ASQC Automotive Division/AIAG 1990), and SEMATECH uses  (SEMATECH, Inc. 1991).

(SEMATECH, Inc. 1991).

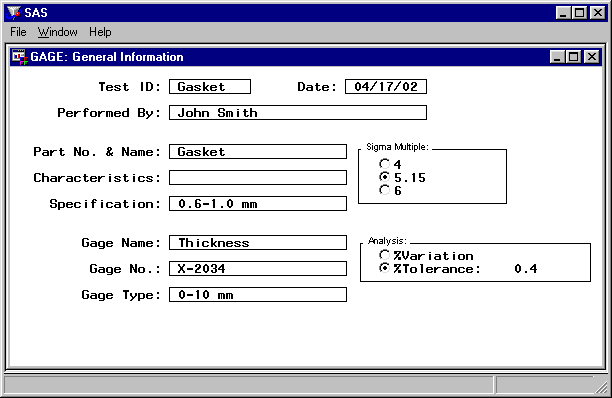

The general information for the gasket thickness gage example is entered, as shown in Figure A.2.

This study is identified with the test ID Gasket. The analysis is based on  , and a percent of tolerance analysis based on a tolerance of 0.4mm is requested.

, and a percent of tolerance analysis based on a tolerance of 0.4mm is requested.

Copyright © SAS Institute, Inc. All Rights Reserved.