| The CAPABILITY Procedure |

Creating a Normal Probability-Probability Plot

[See CAPPP1 in the SAS/QC Sample Library]The distances between two holes cut into 50 steel sheets are measured and saved as values of the variable Distance in the following data set: 1

data Sheets; input Distance @@; label Distance='Hole Distance in cm'; datalines; 9.80 10.20 10.27 9.70 9.76 10.11 10.24 10.20 10.24 9.63 9.99 9.78 10.10 10.21 10.00 9.96 9.79 10.08 9.79 10.06 10.10 9.95 9.84 10.11 9.93 10.56 10.47 9.42 10.44 10.16 10.11 10.36 9.94 9.77 9.36 9.89 9.62 10.05 9.72 9.82 9.99 10.16 10.58 10.70 9.54 10.31 10.07 10.33 9.98 10.15 ; run;

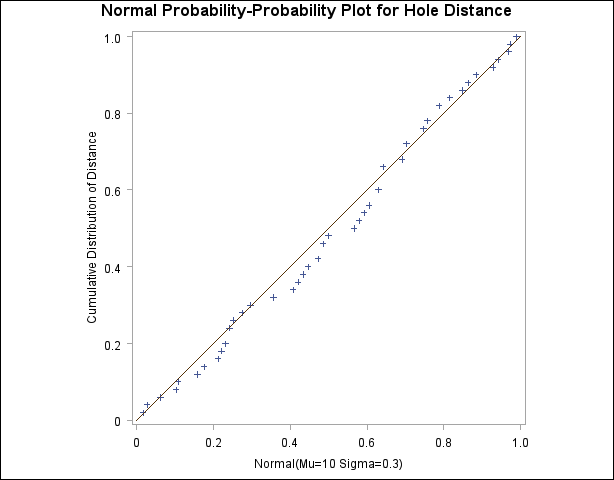

The cutting process is in statistical control. As a preliminary step in a capability analysis of the process, it is decided to check whether the distances are normally distributed. The following statements create a P-P plot, shown in Figure 5.18.3, which is based on the normal distribution with mean  and standard deviation

and standard deviation  :

:

symbol v=plus;

title 'Normal Probability-Probability Plot for Hole Distance';

proc capability data=Sheets noprint;

ppplot Distance / normal(mu=10 sigma=0.3)

square;

run;

The NORMAL option in the PPPLOT statement requests a P-P plot based on the normal cumulative distribution function, and the MU= and SIGMA= normal-options specify  and

and  . Note that a P-P plot is always based on a completely specified distribution, in other words, a distribution with specific parameters. In this example, if you did not specify the MU= and SIGMA= normal-options, the sample mean and sample standard deviation would be used for

. Note that a P-P plot is always based on a completely specified distribution, in other words, a distribution with specific parameters. In this example, if you did not specify the MU= and SIGMA= normal-options, the sample mean and sample standard deviation would be used for  and

and  .

.

The linearity of the pattern in Figure 5.18.3 is evidence that the measurements are normally distributed with mean 10 and standard deviation 0.3. The COLOR= normal-option specifies the color for the diagonal reference line, and the SQUARE option displays the plot in a square format.

Copyright © SAS Institute, Inc. All Rights Reserved.