The Mixed Integer Linear Programming Solver

Example 8.3 Facility Location

Consider the classic facility location problem. Given a set L of customer locations and a set F of candidate facility sites, you must decide on which sites to build facilities and assign coverage of customer demand to

these sites so as to minimize cost. All customer demand  must be satisfied, and each facility has a demand capacity limit C. The total cost is the sum of the distances

must be satisfied, and each facility has a demand capacity limit C. The total cost is the sum of the distances  between facility j and its assigned customer i, plus a fixed charge

between facility j and its assigned customer i, plus a fixed charge  for building a facility at site j. Let

for building a facility at site j. Let  represent choosing site j to build a facility, and 0 otherwise. Also, let

represent choosing site j to build a facility, and 0 otherwise. Also, let  represent the assignment of customer i to facility j, and 0 otherwise. This model can be formulated as the following integer linear program:

represent the assignment of customer i to facility j, and 0 otherwise. This model can be formulated as the following integer linear program:

![\[ \begin{array}{llllll} \min & \displaystyle \sum _{i \in L} \displaystyle \sum _{j \in F} c_{ij} x_{ij} + \displaystyle \sum _{j \in F} f_ j y_ j \\ \mr{s.t.} & \displaystyle \sum _{j \in F} x_{ij} & = & 1 & \forall i \in L & \mr{(assign\_ def)} \\ & x_{ij} & \leq & y_ j & \forall i \in L, j \in F & \mr{(link)}\\ & \displaystyle \sum _{i \in L} d_ i x_{ij} & \leq & Cy_ j & \forall j \in F & \mr{(capacity)} \\ & x_{ij} \in \{ 0,1\} & & & \forall i \in L, j \in F \\ & y_{j} \in \{ 0,1\} & & & \forall j \in F \end{array} \]](images/ormpug_milpsolver0080.png)

Constraint (assign_def) ensures that each customer is assigned to exactly one site. Constraint (link) forces a facility to be built if any customer has been assigned to that facility. Finally, constraint (capacity) enforces the capacity limit at each site.

Consider also a variation of this same problem where there is no cost for building a facility. This problem is typically easier to solve than the original problem. For this variant, let the objective be

![\[ \begin{array}{lllll} \min & \displaystyle \sum _{i \in L} \displaystyle \sum _{j \in F} c_{ij} x_{ij} \end{array} \]](images/ormpug_milpsolver0081.png)

First, construct a random instance of this problem by using the following DATA steps:

title 'Facility Location Problem';

%let NumCustomers = 50;

%let NumSites = 10;

%let SiteCapacity = 35;

%let MaxDemand = 10;

%let xmax = 200;

%let ymax = 100;

%let seed = 938;

/* generate random customer locations */

data cdata(drop=i);

length name $8;

do i = 1 to &NumCustomers;

name = compress('C'||put(i,best.));

x = ranuni(&seed) * &xmax;

y = ranuni(&seed) * &ymax;

demand = ranuni(&seed) * &MaxDemand;

output;

end;

run;

/* generate random site locations and fixed charge */

data sdata(drop=i);

length name $8;

do i = 1 to &NumSites;

name = compress('SITE'||put(i,best.));

x = ranuni(&seed) * &xmax;

y = ranuni(&seed) * &ymax;

fixed_charge = 30 * (abs(&xmax/2-x) + abs(&ymax/2-y));

output;

end;

run;

The following PROC OPTMODEL statements first generate and solve the model with the no-fixed-charge variant of the cost function. Next, they solve the fixed-charge model. Note that the solution to the model with no fixed charge is feasible for the fixed-charge model and should provide a good starting point for the MILP solver. Use the PRIMALIN option to provide an incumbent solution (warm start).

proc optmodel;

set <str> CUSTOMERS;

set <str> SITES init {};

/* x and y coordinates of CUSTOMERS and SITES */

num x {CUSTOMERS union SITES};

num y {CUSTOMERS union SITES};

num demand {CUSTOMERS};

num fixed_charge {SITES};

/* distance from customer i to site j */

num dist {i in CUSTOMERS, j in SITES}

= sqrt((x[i] - x[j])^2 + (y[i] - y[j])^2);

read data cdata into CUSTOMERS=[name] x y demand;

read data sdata into SITES=[name] x y fixed_charge;

var Assign {CUSTOMERS, SITES} binary;

var Build {SITES} binary;

min CostNoFixedCharge

= sum {i in CUSTOMERS, j in SITES} dist[i,j] * Assign[i,j];

min CostFixedCharge

= CostNoFixedCharge + sum {j in SITES} fixed_charge[j] * Build[j];

/* each customer assigned to exactly one site */

con assign_def {i in CUSTOMERS}:

sum {j in SITES} Assign[i,j] = 1;

/* if customer i assigned to site j, then facility must be built at j */

con link {i in CUSTOMERS, j in SITES}:

Assign[i,j] <= Build[j];

/* each site can handle at most &SiteCapacity demand */

con capacity {j in SITES}:

sum {i in CUSTOMERS} demand[i] * Assign[i,j] <=

&SiteCapacity * Build[j];

/* solve the MILP with no fixed charges */

solve obj CostNoFixedCharge with milp / logfreq = 500;

/* clean up the solution */

for {i in CUSTOMERS, j in SITES} Assign[i,j] = round(Assign[i,j]);

for {j in SITES} Build[j] = round(Build[j]);

call symput('varcostNo',put(CostNoFixedCharge,6.1));

/* create a data set for use by GPLOT */

create data CostNoFixedCharge_Data from

[customer site]={i in CUSTOMERS, j in SITES: Assign[i,j] = 1}

xi=x[i] yi=y[i] xj=x[j] yj=y[j];

/* solve the MILP, with fixed charges with warm start */

solve obj CostFixedCharge with milp / primalin logfreq = 500;

/* clean up the solution */

for {i in CUSTOMERS, j in SITES} Assign[i,j] = round(Assign[i,j]);

for {j in SITES} Build[j] = round(Build[j]);

num varcost = sum {i in CUSTOMERS, j in SITES} dist[i,j] * Assign[i,j].sol;

num fixcost = sum {j in SITES} fixed_charge[j] * Build[j].sol;

call symput('varcost', put(varcost,6.1));

call symput('fixcost', put(fixcost,5.1));

call symput('totalcost', put(CostFixedCharge,6.1));

/* create a data set for use by GPLOT */

create data CostFixedCharge_Data from

[customer site]={i in CUSTOMERS, j in SITES: Assign[i,j] = 1}

xi=x[i] yi=y[i] xj=x[j] yj=y[j];

quit;

The information printed in the log for the no-fixed-charge model is displayed in Output 8.3.1.

Output 8.3.1: OPTMODEL Log for Facility Location with No Fixed Charges

| NOTE: Problem generation will use 4 threads. |

| NOTE: The problem has 510 variables (0 free, 0 fixed). |

| NOTE: The problem has 510 binary and 0 integer variables. |

| NOTE: The problem has 560 linear constraints (510 LE, 50 EQ, 0 GE, 0 range). |

| NOTE: The problem has 2010 linear constraint coefficients. |

| NOTE: The problem has 0 nonlinear constraints (0 LE, 0 EQ, 0 GE, 0 range). |

| NOTE: The MILP presolver value AUTOMATIC is applied. |

| NOTE: The MILP presolver removed 10 variables and 500 constraints. |

| NOTE: The MILP presolver removed 1010 constraint coefficients. |

| NOTE: The MILP presolver modified 0 constraint coefficients. |

| NOTE: The presolved problem has 500 variables, 60 constraints, and 1000 |

| constraint coefficients. |

| NOTE: The MILP solver is called. |

| NOTE: The parallel Branch and Cut algorithm is used. |

| NOTE: The Branch and Cut algorithm is using up to 4 threads. |

| Node Active Sols BestInteger BestBound Gap Time |

| 0 1 2 972.1737321 0 972.2 0 |

| 0 1 2 972.1737321 961.2403449 1.14% 0 |

| 0 1 2 972.1737321 961.2403449 1.14% 0 |

| 0 1 2 972.1737321 961.2403449 1.14% 0 |

| NOTE: The MILP presolver is applied again. |

| 0 1 4 966.4832160 962.9120804 0.37% 0 |

| 0 1 5 966.4832160 966.4832160 0.00% 0 |

| 0 0 5 966.4832160 966.4832160 0.00% 0 |

| NOTE: The MILP solver added 0 cuts with 0 cut coefficients at the root. |

| NOTE: Optimal. |

| NOTE: Objective = 966.48321599. |

The results from the warm start approach are shown in Output 8.3.2.

Output 8.3.2: OPTMODEL Log for Facility Location with Fixed Charges, Using Warm Start

| NOTE: Problem generation will use 4 threads. |

| NOTE: The problem has 510 variables (0 free, 0 fixed). |

| NOTE: The problem uses 1 implicit variables. |

| NOTE: The problem has 510 binary and 0 integer variables. |

| NOTE: The problem has 560 linear constraints (510 LE, 50 EQ, 0 GE, 0 range). |

| NOTE: The problem has 2010 linear constraint coefficients. |

| NOTE: The problem has 0 nonlinear constraints (0 LE, 0 EQ, 0 GE, 0 range). |

| NOTE: The MILP presolver value AUTOMATIC is applied. |

| NOTE: The MILP presolver removed 0 variables and 0 constraints. |

| NOTE: The MILP presolver removed 0 constraint coefficients. |

| NOTE: The MILP presolver modified 0 constraint coefficients. |

| NOTE: The presolved problem has 510 variables, 560 constraints, and 2010 |

| constraint coefficients. |

| NOTE: The MILP solver is called. |

| NOTE: The parallel Branch and Cut algorithm is used. |

| NOTE: The Branch and Cut algorithm is using up to 4 threads. |

| Node Active Sols BestInteger BestBound Gap Time |

| 0 1 3 16070.0150023 0 16070 0 |

| 0 1 3 16070.0150023 9946.2514269 61.57% 0 |

| 0 1 3 16070.0150023 9962.4849932 61.31% 0 |

| 0 1 3 16070.0150023 9971.5893075 61.16% 0 |

| 0 1 3 16070.0150023 9974.5588580 61.11% 0 |

| 0 1 3 16070.0150023 9978.1322942 61.05% 0 |

| 0 1 3 16070.0150023 9978.3312183 61.05% 0 |

| 0 1 3 16070.0150023 9980.4930282 61.01% 0 |

| 0 1 3 16070.0150023 9981.2701907 61.00% 0 |

| 0 1 4 16009.9864088 9981.2701907 60.40% 0 |

| NOTE: The MILP solver added 20 cuts with 631 cut coefficients at the root. |

| 207 181 5 14940.8468978 10254.0277196 45.71% 0 |

| 244 203 6 11574.7346191 10366.4971368 11.66% 0 |

| 304 250 7 11200.4907322 10384.6282929 7.86% 0 |

| 464 318 8 10952.9510709 10474.3603655 4.57% 0 |

| 500 339 8 10952.9510709 10548.0238535 3.84% 0 |

| 548 368 9 10951.0805543 10548.0238535 3.82% 0 |

| 560 374 10 10951.0805542 10548.0238535 3.82% 0 |

| 642 6 11 10950.0345546 10946.4429359 0.03% 0 |

| 660 0 12 10948.4603464 10948.4603464 0.00% 0 |

| NOTE: Optimal. |

| NOTE: Objective = 10948.460346. |

The following two SAS programs produce a plot of the solutions for both variants of the model, using data sets produced by PROC OPTMODEL:

title1 h=1.5 "Facility Location Problem";

title2 "TotalCost = &varcostNo (Variable = &varcostNo, Fixed = 0)";

data csdata;

set cdata(rename=(y=cy)) sdata(rename=(y=sy));

run;

/* create Annotate data set to draw line between customer and assigned site */

%annomac;

data anno(drop=xi yi xj yj);

%SYSTEM(2, 2, 2);

set CostNoFixedCharge_Data(keep=xi yi xj yj);

%LINE(xi, yi, xj, yj, *, 1, 1);

run;

proc gplot data=csdata anno=anno;

axis1 label=none order=(0 to &xmax by 10);

axis2 label=none order=(0 to &ymax by 10);

symbol1 value=dot interpol=none

pointlabel=("#name" nodropcollisions height=1) cv=black;

symbol2 value=diamond interpol=none

pointlabel=("#name" nodropcollisions color=blue height=1) cv=blue;

plot cy*x sy*x / overlay haxis=axis1 vaxis=axis2;

run;

quit;

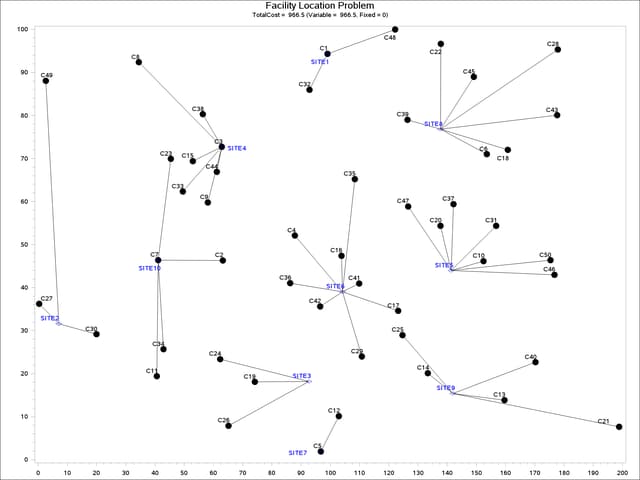

The output of the first program is shown in Output 8.3.3.

Output 8.3.3: Solution Plot for Facility Location with No Fixed Charges

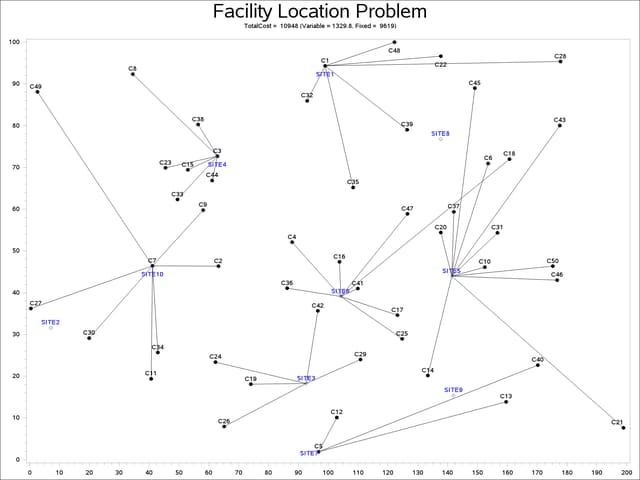

The output of the second program is shown in Output 8.3.4.

title1 "Facility Location Problem";

title2 "TotalCost = &totalcost (Variable = &varcost, Fixed = &fixcost)";

/* create Annotate data set to draw line between customer and assigned site */

data anno(drop=xi yi xj yj);

%SYSTEM(2, 2, 2);

set CostFixedCharge_Data(keep=xi yi xj yj);

%LINE(xi, yi, xj, yj, *, 1, 1);

run;

proc gplot data=csdata anno=anno;

axis1 label=none order=(0 to &xmax by 10);

axis2 label=none order=(0 to &ymax by 10);

symbol1 value=dot interpol=none

pointlabel=("#name" nodropcollisions height=1) cv=black;

symbol2 value=diamond interpol=none

pointlabel=("#name" nodropcollisions color=blue height=1) cv=blue;

plot cy*x sy*x / overlay haxis=axis1 vaxis=axis2;

run;

quit;

Output 8.3.4: Solution Plot for Facility Location with Fixed Charges

The economic trade-off for the fixed-charge model forces you to build fewer sites and push more demand to each site.

It is possible to expedite the solution of the fixed-charge facility location problem by choosing appropriate branching priorities

for the decision variables. Recall that for each site j, the value of the variable  determines whether or not a facility is built on that site. Suppose you decide to branch on the variables

determines whether or not a facility is built on that site. Suppose you decide to branch on the variables  before the variables

before the variables  . You can set a higher branching priority for

. You can set a higher branching priority for  by using the

by using the .priority suffix for the Build variables in PROC OPTMODEL, as follows:

for{j in SITES} Build[j].priority=10;

Setting higher branching priorities for certain variables is not guaranteed to speed up the MILP solver, but it can be helpful

in some instances. The following program creates and solves an instance of the facility location problem, giving higher priority

to the variables  . The LOGFREQ=

option is used to abbreviate the node log.

. The LOGFREQ=

option is used to abbreviate the node log.

%let NumCustomers = 45;

%let NumSites = 8;

%let SiteCapacity = 35;

%let MaxDemand = 10;

%let xmax = 200;

%let ymax = 100;

%let seed = 2345;

/* generate random customer locations */

data cdata(drop=i);

length name $8;

do i = 1 to &NumCustomers;

name = compress('C'||put(i,best.));

x = ranuni(&seed) * &xmax;

y = ranuni(&seed) * &ymax;

demand = ranuni(&seed) * &MaxDemand;

output;

end;

run;

/* generate random site locations and fixed charge */

data sdata(drop=i);

length name $8;

do i = 1 to &NumSites;

name = compress('SITE'||put(i,best.));

x = ranuni(&seed) * &xmax;

y = ranuni(&seed) * &ymax;

fixed_charge = (abs(&xmax/2-x) + abs(&ymax/2-y)) / 2;

output;

end;

run;

proc optmodel;

set <str> CUSTOMERS;

set <str> SITES init {};

/* x and y coordinates of CUSTOMERS and SITES */

num x {CUSTOMERS union SITES};

num y {CUSTOMERS union SITES};

num demand {CUSTOMERS};

num fixed_charge {SITES};

/* distance from customer i to site j */

num dist {i in CUSTOMERS, j in SITES}

= sqrt((x[i] - x[j])^2 + (y[i] - y[j])^2);

read data cdata into CUSTOMERS=[name] x y demand;

read data sdata into SITES=[name] x y fixed_charge;

var Assign {CUSTOMERS, SITES} binary;

var Build {SITES} binary;

min CostFixedCharge

= sum {i in CUSTOMERS, j in SITES} dist[i,j] * Assign[i,j]

+ sum {j in SITES} fixed_charge[j] * Build[j];

/* each customer assigned to exactly one site */

con assign_def {i in CUSTOMERS}:

sum {j in SITES} Assign[i,j] = 1;

/* if customer i assigned to site j, then facility must be built at j */

con link {i in CUSTOMERS, j in SITES}:

Assign[i,j] <= Build[j];

/* each site can handle at most &SiteCapacity demand */

con capacity {j in SITES}:

sum {i in CUSTOMERS} demand[i] * Assign[i,j] <= &SiteCapacity * Build[j];

/* assign priority to Build variables (y) */

for{j in SITES} Build[j].priority=10;

/* solve the MILP with fixed charges, using branching priorities */

solve obj CostFixedCharge with milp / logfreq=1000;

quit;

The resulting output is shown in Output 8.3.5.

Output 8.3.5: PROC OPTMODEL Log for Facility Location with Branching Priorities

| NOTE: There were 45 observations read from the data set WORK.CDATA. |

| NOTE: There were 8 observations read from the data set WORK.SDATA. |

| NOTE: Problem generation will use 4 threads. |

| NOTE: The problem has 368 variables (0 free, 0 fixed). |

| NOTE: The problem has 368 binary and 0 integer variables. |

| NOTE: The problem has 413 linear constraints (368 LE, 45 EQ, 0 GE, 0 range). |

| NOTE: The problem has 1448 linear constraint coefficients. |

| NOTE: The problem has 0 nonlinear constraints (0 LE, 0 EQ, 0 GE, 0 range). |

| NOTE: The MILP presolver value AUTOMATIC is applied. |

| NOTE: The MILP presolver removed 0 variables and 0 constraints. |

| NOTE: The MILP presolver removed 0 constraint coefficients. |

| NOTE: The MILP presolver modified 0 constraint coefficients. |

| NOTE: The presolved problem has 368 variables, 413 constraints, and 1448 |

| constraint coefficients. |

| NOTE: The MILP solver is called. |

| NOTE: The parallel Branch and Cut algorithm is used. |

| NOTE: The Branch and Cut algorithm is using up to 4 threads. |

| Node Active Sols BestInteger BestBound Gap Time |

| 0 1 3 2823.1827978 0 2823.2 0 |

| 0 1 3 2823.1827978 1727.0208789 63.47% 0 |

| 0 1 3 2823.1827978 1756.0637224 60.77% 0 |

| 0 1 5 1906.4633474 1764.3961986 8.05% 0 |

| 0 1 5 1906.4633474 1772.0991932 7.58% 0 |

| 0 1 5 1906.4633474 1784.2955379 6.85% 0 |

| 0 1 5 1906.4633474 1788.0570704 6.62% 0 |

| 0 1 5 1906.4633474 1788.0570704 6.62% 0 |

| NOTE: The MILP presolver is applied again. |

| 0 1 5 1906.4633474 1788.0570704 6.62% 0 |

| 0 1 5 1906.4633474 1788.0570704 6.62% 0 |

| 0 1 5 1906.4633474 1788.0570704 6.62% 0 |

| 0 1 5 1906.4633474 1788.0570704 6.62% 0 |

| 0 1 5 1906.4633474 1788.0570704 6.62% 0 |

| 0 1 5 1906.4633474 1788.1857838 6.61% 0 |

| 0 1 5 1906.4633474 1793.0963734 6.32% 0 |

| 0 1 5 1906.4633474 1793.5540695 6.30% 0 |

| 0 1 5 1906.4633474 1793.6034154 6.29% 0 |

| 0 1 5 1906.4633474 1793.7200171 6.29% 0 |

| 0 1 5 1906.4633474 1793.7651419 6.28% 0 |

| 0 1 6 1903.8518326 1793.7651419 6.14% 0 |

| NOTE: The MILP solver added 28 cuts with 666 cut coefficients at the root. |

| 209 182 7 1826.3615927 1800.9334244 1.41% 0 |

| 816 46 8 1823.4483963 1805.5532343 0.99% 0 |

| 1000 195 8 1823.4483963 1808.1519690 0.85% 0 |

| 1390 397 9 1823.4483963 1811.0458067 0.68% 0 |

| 1845 352 10 1819.9124343 1814.9424888 0.27% 1 |

| 2000 153 10 1819.9124343 1817.0347069 0.16% 1 |

| 2167 7 10 1819.9124343 1819.7338302 0.01% 1 |

| NOTE: Optimal within relative gap. |

| NOTE: Objective = 1819.9124343. |