Miscellaneous Reports

In addition to the Summarized Parts List and Indented BOM reports described in the section Product Structure Reports, the output from PROC BOM and the BOM reporting macros can also be used to generate summarized bills of material, gross requirement summaries, and where-used lists.

Summarized BOM

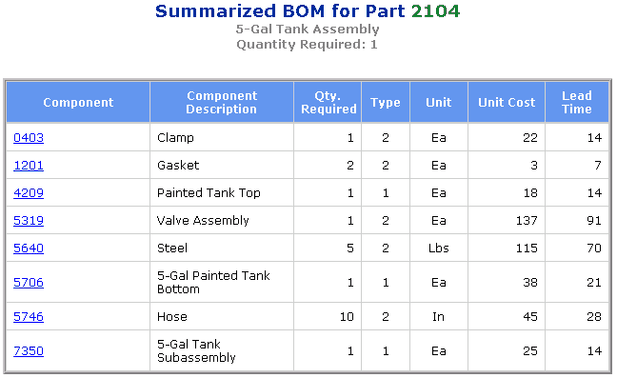

The Summarized BOM for an item describes all the parts and their total quantity required in the production of the item. For each component, the Summarized BOM lists the following information:

-

Part number and description for the component

-

Quantity required to make one unit of the end item

-

Item type

-

Unit of measure

-

Unit cost

-

Lead time

The Summarized BOM for the 5-Gal Tank Assembly in the BOM Web example is shown in Figure A.8. Chapter 4 describes a macro, %BOMRSUB, that constructs a summarized bill of material for a selected item.

Figure A.8: Summarized BOM

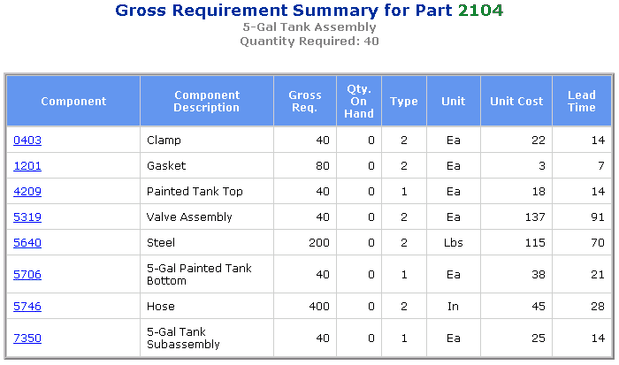

Gross Requirement Summary

The Gross Requirement Summary for an item lists the quantities of all components needed to produce the required quantity of the item. This report enables you to analyze how future orders for an item will impact inventory levels. See the section Summarized Parts Data Set and Example 3.9 in Chapter 3 for details about the gross requirement calculation.

For each component, the Gross Requirement Summary includes the following:

-

Part number and description for the component

-

Quantity required

-

Quantity on hand

-

Item type

-

Unit of measure

-

Unit cost

-

Lead time

Figure A.9 shows the Gross Requirement Summary report for the 5-Gal Tank Assembly with a required quantity of 40. Notice that this report is similar to the Summarized BOM in Figure A.8, with a column “Gross Req.” that is 40 times the “Qty. Required” column from the Summarized BOM. The Gross Requirement Summary also includes a column for quantity on hand for inventory status information to compare with component requirements.

Figure A.9: Gross Requirement Summary

Where-Used Reports

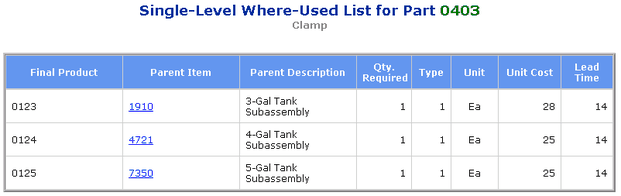

The Single-Level Where-Used report for an item lists each parent in which that item is directly used and in what quantity. For each parent item, the Single-Level Where-Used report lists the following:

-

Part number and description for the parent item

-

Quantity required

-

Item type

-

Unit of measure

-

Unit cost

-

Lead time

The Single-Level Where-Used report for the Clamp is shown in Figure A.10. Chapter 4 describes a macro, %BOMRSLW, that constructs a single-level where-used list for a selected item.

Figure A.10: Single-Level Where-Used Report

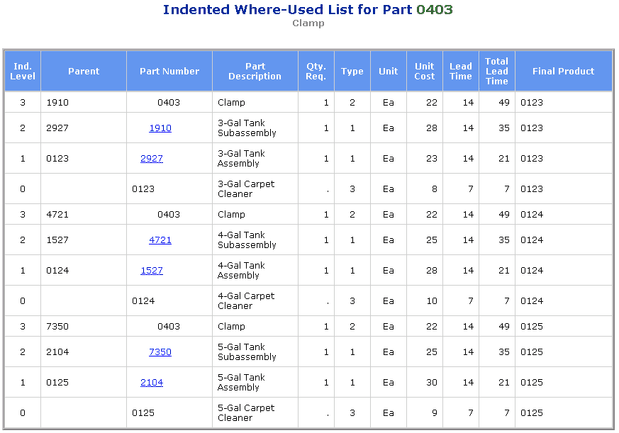

The Indented Where-Used report for an item traces its use through the indented bill of material. This report lists the item and steps through each higher-level component or assembly using the item until a final product is reached. At each level, for the current part or assembly, the Indented Where-Used report lists the following:

-

Indentation level

-

Part number for the parent item

-

Part number and description

-

Quantity required

-

Item type

-

Unit of measure

-

Unit cost

-

Lead time and total lead time

-

Final product

The Indented Where-Used report for the Clamp is shown in Figure A.11. Chapter 4 describes a macro, %BOMRMLW, that constructs an indented where-used list for a selected item.

Figure A.11: Indented Where-Used Report

In addition, the %BOMRSUW macro can be used to construct a summarized where-used list for a selected item, which lists the total usage of this item for every higher-level parent using it. See Chapter 4 for more information on these BOM reporting macros.