Entities that represent the parts are created in the Arrivals compound block and are pushed to a Delay compound block where

they are held for one minute, representing the travel time between stations. Next they are pushed to the Service DeskQ Queue

block where they wait for the next available associate at the service desk. After service is completed at the service desk,

the entity is pushed to a Chance compound block, which is used to model branching based on probability (in particular, to

model that ![]() of the parts are repaired at the service desk while the rest are sent on to the repair station).

of the parts are repaired at the service desk while the rest are sent on to the repair station).

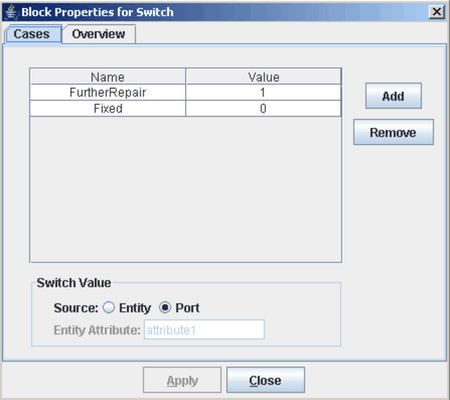

If you right-click the Switch block inside the first Chance compound block to open the properties dialog box, you see that two cases are defined: one named FurtherRepair and one named Fixed. (See Figure 2.8.) The Port option indicates that the switch value comes through the InSwitchValue port. After the two cases have been defined, two additional entity output ports are dynamically created on the Switch block to allow routing of entities based on the switch value. The InSwitchValue port is connected to a Formula block.

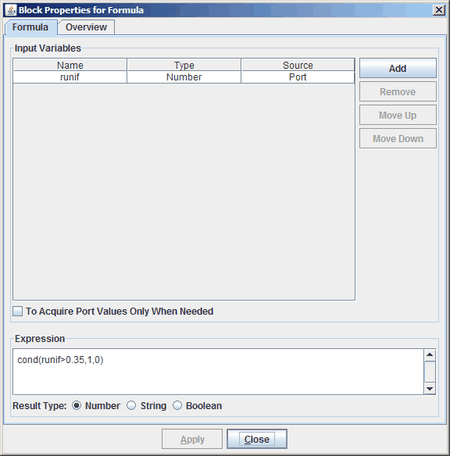

Figure 2.9 shows the properties dialog box for the Formula block. After you add one input variable named runif of type Number, the Formula block dynamically creates an input port labeled runif. Connected to the runif input port is a Numeric Source block. This Numeric Source block generates a sample from the uniform distribution with a minimum

of 0 and a maximum of 1. After the value for runif is pulled by the Formula block, the expression cond(runif>0.35,1,0) is evaluated as follows: If runif is greater than 0.35, then the value 1 is returned and pushed out of the Formula block and into the Switch block. Otherwise,

the value 0 is returned and pushed out. The Switch block then receives either the value of 1 or 0 and uses the value to determine

which output port the entity should use to leave the Switch block.

If a part is fixed at the service desk, it leaves the system. Otherwise, it is pushed on to the second Delay compound block

where it is held for one minute. It then waits in the repair desk queue for the next available repairman. After being serviced

by a repairman, the part is pushed into the second Chance block. Here the expression cond(runif>0.09,1,0) is evaluated so that with probability 0.09 the part cannot be fixed and is scrapped (that is, the entity leaves the system).

Parts that are fixed move on to the third Delay compound block where they wait for one minute and then are pushed into the

quality control queue. After being inspected by the quality control manager, the condition cond(runif>0.10,1,0) is evaluated so that with probability 0.10 the part does not pass the quality control inspection and is sent back (via the

Connector labeled Rework) to the Repair Desk queue. Parts that do pass the quality control inspection leave the system.