The SHEWHART Procedure

Applying Tests with Multiple Sets of Control Limits

Note: See Applying Tests with Multiple Control Limits in the SAS/QC Sample Library.

This example is a continuation of the previous example, except that distinct control limits are displayed for each of the

phases determined by the variable System. The control limit parameters (mean, standard deviation, and nominal sample size) for each phase (manufacturing system) are

provided in the following data set:

data Syslim;

length _var_ $8 _subgrp_ $8 _type_ $8 _index_ $1;

input _var_ _subgrp_ _index_ _type_ _mean_ _stddev_

_limitn_ _sigmas_;

datalines;

Offset Sample R standard 20.5 2.02 5 3

Offset Sample Q standard 20.2 2.35 7 3

Offset Sample T standard 20.0 2.24 5 3

;

The following statements read the control limit parameters from Syslim and use the READPHASES=

and READINDEXES=

options to display a distinct set of control limits for each phase:

ods graphics off;

title 'System-Specific Control Limits';

proc shewhart

limits=Syslim

history=Assembly (rename=(System=_phase_));

xrchart Offset * Sample /

tests = 1 to 4

testlabel = ( comment )

readindexes = ('T' 'R' 'Q')

readphases = ('T' 'R' 'Q')

phaselegend

phaseref

phasebreak

vaxis = 16 to 26 by 2

split = '/' ;

label OffsetX = 'Avg Offset in cm/Range';

run;

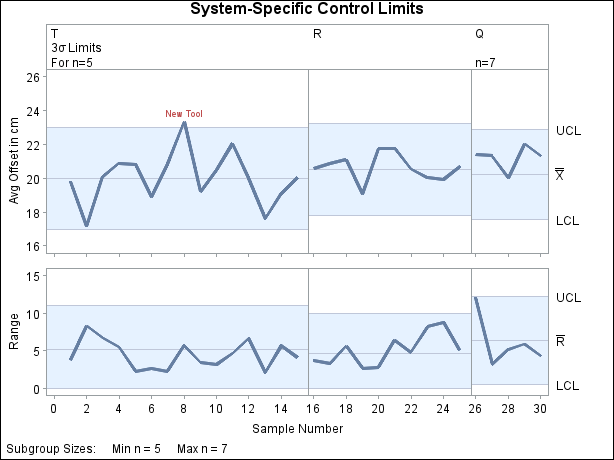

The chart is shown in Figure 18.185. The tests requested with the TESTS= option are applied strictly within the phases, because the control limits are not constant across the phases (as in Figure 18.184). In particular, note that the pattern labeled Reset Tool in Figure 18.184 is not detected in Figure 18.185.

Figure 18.185: Multiple Sets of Control Limits

In most applications involving multiple control limits, a known change or improvement has occurred at the beginning of each phase; consequently, it is appropriate to restart the tests at the beginning of each phase rather than search for patterns that span the boundaries of consecutive phases. In these situations, the PHASEBREAK option is useful for suppressing the connection of points from one phase to the next. Note that it is not necessary to specify the TESTNMETHOD= option here because the subgroup sample sizes are constant within each phase.

There might be applications in which it is appropriate to apply the tests across phase boundaries. You can use the TESTACROSS option to request this behavior.

ods graphics off;

title 'System-Specific Control Limits';

proc shewhart

limits=Syslim

history=Assembly (rename=(System=_phase_));

xrchart Offset * Sample /

tests = 1 to 4

testlabel = ( comment )

testnmethod = standardize

testacross

readindexes = ('T' 'R' 'Q')

readphases = ('T' 'R' 'Q')

phaselegend

phaseref

vaxis = 16 to 26 by 2

split = '/';

label OffsetX = 'Avg Offset in cm/Range';

run;

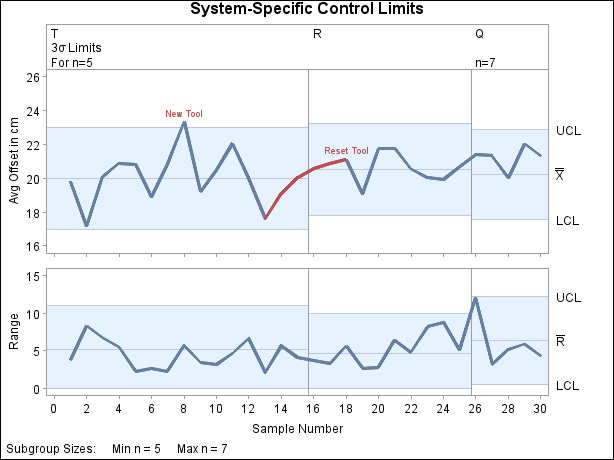

The chart created with the TESTACROSS option is displayed in Figure 18.186.

Figure 18.186: Multiple Sets of Control Limits with the TESTACROSS Option

Here, it is necessary to specify TESTNMETHOD=STANDARDIZE in conjunction with the TESTACROSS option, because the subgroup sample sizes are not constant across phases.

Although Test 3 is now signaled at sample 18, this result should be interpreted with care because the test is applied to standardized

average offsets, and the averages for samples 13, 14, and 15 are standardized differently than the averages for samples 16,

17, and 18. If, for instance, the value of _MEAN_ for phase 'R' in Syslim were 21.0 rather than 20.5, the standardized mean for sample 16 would be less than the standardized mean for sample 15, and

Test 3 would not be signaled at sample 18.

In summary, when working with multiple control limits, you should

-

use the TESTACROSS option only if the process is operating in a continuous manner across phases

-

use TESTNMETHOD=STANDARDIZE only if it is clearly understood by users that tests signaled on the chart are based on standardized statistics rather than the plotted statistics