|

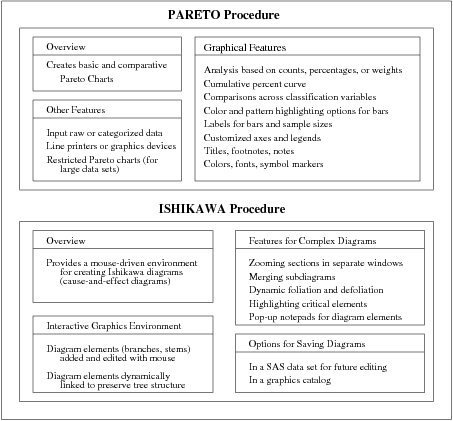

The PARETO procedure creates charts that display the relative frequency of problems in a process or operation. The ISHIKAWA procedure creates a cause-and-effect or fishbone diagram, which displays factors that affect a quality characteristic or problem.